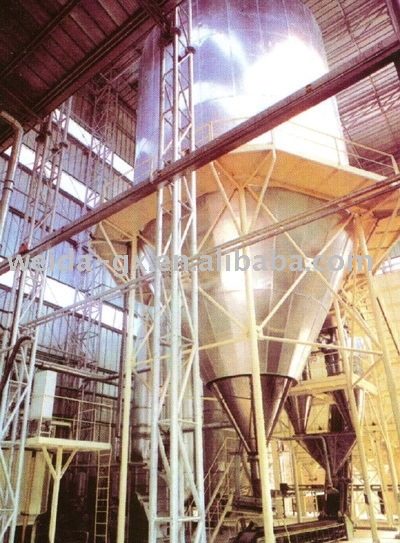

Spray Drier

| Type:Spray Drying Equipment | Place of Origin:China (Mainland) | Brand Name:Weida | Model Number:All types |

Equipment instruction:

This series of the spray drier is used to produce powder material in the industries of building ceramic, daily-used ceramic electro porcelains, and chemicals, food, medicine, farmpesticides, and metallurgy. This equipment was used the midlle press(2Mpa) slop pump to press the material to pulverization, though the sirocco drier, and then to ball smell, and then discharged out from the bottom of pagoda, the exhaust gas was cleansed twice by the cyclone dust catcher and the wet dust catcher, and then discharged from the somkestack. This machine works continuously and uniform for the moisture and the fluidity of dried powder, especially good for mixing used for automatism.

All types of this series spray drier:

WD645, WD6410, WD6415, WD6420, WD6425, WD6432, WD6440, WD6450, WD6460, WD6472, WD6480, WD64100.

The same characters:

Containing water rate of mud: 30%-40% (Density:1.3-1.6g/cm3)

Mud of viscosity: 1000centuples/cp

Containing water rate of powder: 4%-9%

Hot air temperature of tower inlet: 400oC-600oC

Hot air temperature of tower outlet: 80oC-100oC

Inward vacuum of tower: 100-300Pa

Fuel: heavy oil, diesel, natural gas, coal block.

| Packaging Detail:standard export packing |

| Delivery Detail:one month |