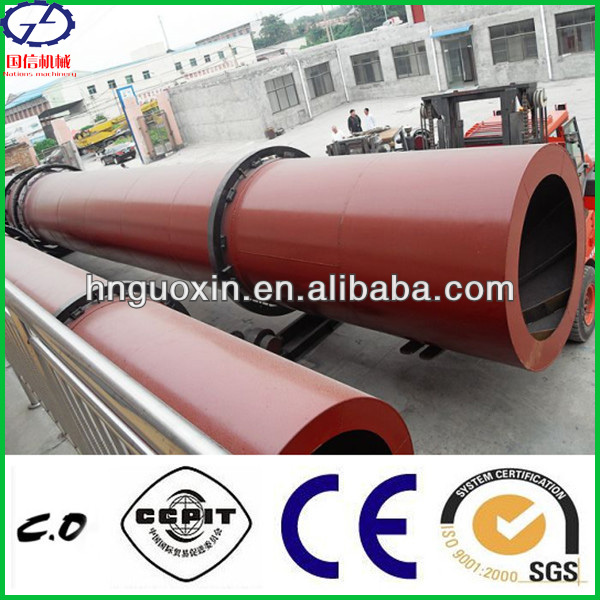

Specialized in Drying High Humidity Materials Sawdust Drying Machine

| Condition:New | Type:Rotary Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:GUOXIN |

| Model Number:GX-1.8*16m | Voltage:Custom made | Power(W):4000-37000 | Dimension(L*W*H):Diameter 1.8x16m(length) |

| Certification:CE, OEM approved | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas | Installation:engineer give technical guidance |

| Capacity:improved 15% | Structure:higher degree of mechanization | Applications:saw dust, wood chip, bagasse, pomace,straw. | Time delivery:within 12 days |

What should we pay more attention to the safetly when running the Drying Machine?

1. Safe Tips for the Drying Machine

- When operation the drying machine, the machine operator should take the initiative to maintain 500mm distance divide the wheel avoiding in the road or track back feet were crushed in the process.

- Before loading of goods, please fill in the uniform of the material on the conveyor, conveyor so as to stop causing congestion.

- When the machine is in operation, prohibiting within half a meter to stand.

- It’s prohibited fireworks in the driving environment and work preventing fire accidents.

- During is in operation. Please fixed time check the temperature on the thermometer index.

2. Note Warning Signs for the Drying Machine

- Read the instructions carefully before operate the machine

- The machine is running around non stop people

- Safe distance The nearest distance operate stand is 500mm

3. Safety Operation for Drying Machine

- Fire prevention maesures: If our equipment is drying easy to ingnite materials, for examply, sawdust, please take care of the dryer on the thermometer, if abnormal, please immediately stop the operation, staff should always control the entry of fuel to feed evenly, do not off.

- Protection against smoke rise: When working in the building, make sure that enough ventilation, do not produce so much smoke, leading to staff safety.

Technical Parameter of Drying Machine

| Model | Reducer Model | Reducer Ratio | Speed (r/min) | Capacity (t/h) | Power (KW) | Weight (ton) |

| Φ 0.8x10 | JZQ450-16-II | 7.2 | 0.8-2.2 | 4 | 5.1 | |

| Φ 1.0x10 | JZQ450-16-II | 6.73 | 1-3.8 | 5.5 | 7.5 | |

| Φ 1.2x12 | ZL50-16-I | 5.8 | 1.8-5.5 | 11 | 13.8 | |

| Φ 1.5x12 | JZQ5000-III-2F | 16.46 | 4.8 | 4-9 | 15 | 22.3 |

| Φ 1.5x16 | ZQ50-16II-2 | 16.46 | 4.8 | 4-10 | 18.5 | 28.8 |

| Φ 1.8x16 | JZQ650-III | 18.84 | 3.2 | 6-12 | 22 | 39.8 |

| Φ 2.0x18 | JZQ650-III | 31.5 | 3 | 10-20 | 30 | 40.5 |

| Φ 2.2x20 | JZQ750-III | 31.5 | 3 | 10-25 | 37 | 48.3 |

| Φ 2.4x20 | ZL85-13-I | 27.16 | 2.83 | 20-40 | 45 | 51 |

Wide Applications of Drying Machine

- Sawdust, wood chips, palm kernel sheel, palm fiber, tobacco leaf, vinasse, bagasse, pomace, eucalyptus leaf, rice husk, and other Agroforestry Wastes.

- Sand, lime, flourite powder, slurry, flue gas desulfurization gypsum, slag, clay stone, building materials.

- High moisture coal powder, coal slurry, all kinds of mineral powder, milltaillings, lignite, industrial & mineral industry materials.

- Chicken manure, compound fertilizer, organic fertilizer, cow dung, etc.

Working Principle of Drying Machine

Drying Machine is suitable for drying various types of wet materials which the moisture content is less than 58%.

1. First, wet materials will be puted into drying machine cylinder by belt conveyor, flied by raising plates which are uniform distribution in the drum cylinder.

2. The wet materials are evenly distributed inside of drying machine, thus it will fully contact with the hot-air, speed up the drying heat and mass transfer.

3. Drying for a period of time, under the effect of plates and hot treatment in the drying machine, the wet materials are dried well.

4. Finally, the dried materials come out of form the discharge device of sand dryer, and the temperature is around 70-80 centigrade.

After-Sale Service for Drying Machine

- Before everything, we should talk about the raw material, its moisture, capacity you need, matters need attention during drying

- Suggesting you suitable coal dryer such as different diameter: 1.5m,1.8m,2.0m, 2.2m and making sure the width and length of coal dryer.

- Solving all of your questions, whether technology, shipping, installation or operation.

- Training technical personnel for customers

- When the dryer is shipped to working-site, our engineer will offer guidance for installing and debuging equipments.

| Packaging Detail:Standard container |

| Delivery Detail:Within 15 days after receiving 30% prepayment |