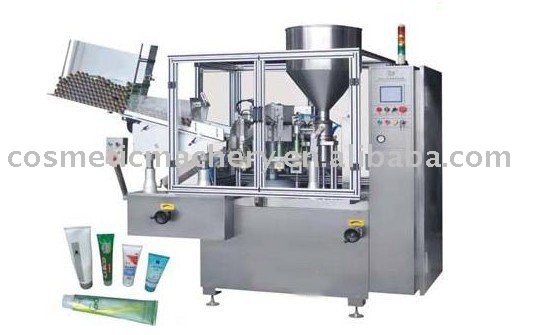

Soft Tube/ Cosmetic /toothpaste/pharmaceutics/food/Filling and Sealing packing Machine

| Condition:New | Application:Chemical | Packaging Type:Cartons | Packaging Material:Wood |

| Automatic Grade:Automatic | Driven Type:Electric | Power:3KW | Place of Origin:Guangdong China (Mainland) |

| Brand Name:yuxiang | Model Number:GZFW | Type:Sealing Machine,Filling Machine |

Sealing Machine

1,Purpose

This machine is suitable for operating filling, sealing a quantity of viscosity of oil, cream and gel etc ointment.

2,Main Technical Parameter

3,Working principle

Model GF-400 L(F) Automatic Tube Filling And Sealing Machine is designed for ALU tube, plastic tube and multiple tube filling and sealing in cosmetic, pharmacy, foodstuff, adhesives etc industries. It’s operating principle is to put the pipes which is in the feeder hopper into the first service position filling model individually, to invert with rotating disk, to test nomenclature plate in pipe when inverting to the second , to fill with nitrogen gas into pipe in the third, to fill with desired substance in the fourth, then to fix the heating, folding, jamming, number printing, cooling, slivers trimming etc service position, to export the finished products when inverting to the last service position so the twelfth. Every pipe should take such series process to filling, sealing to completion.

4,Capability and features

Accuracy filling, balanced action, low buzz.

1. Automatically finished overall process as tube supply, photoelectron register, inert gases filling (optional), material filling and sealing, batch number printing, finished products output.

2. Adjust position outlay and position numbers video picture, quickly and accurately adjustment ( suitable for varies specification and varies product producing )

3. Mechanical, photoelectron, electric, pheumatic intergrative controlling, reaches no tube no filling function; warning if tube error positioned or pressure too low, automatic stop machine if open the protective door.

5,Reliability

1. The part contact direct with ointment adopts 304L or 316L stainless steel. It use materials that is non-poisonous, no reaction with drug, non-corroding, no absorption from drug.

2. Inner workshop should smears anti rust coat that withstand weak acid and weak base besides adopts austenite stainless steel. The parts with chemical treatment should have no rusteaten and no exfoliation.

3. External surface should adopts austenite stainless steel wiredrawing board or sub-light treatment.

4. Semi-closed outline board visible window adopts bright, staticfree material as closed retaining band.

- Table-board adopts nodular graphite foundry iron. It takes stress relieving, annealing and natural seasoning treatment to reduce distortion after usage.

Soft Tube Filling and Sealing Machine is suitable for filling all kinds of pasty and viscous fluid.

Tube Filling and Sealing Machine is suitable for fillingall kindsof pasty and viscous fluid and the materials alike, into plastic and composite metal tubes and then internally heating tubes, sealing and printing lot number.

It is used in the industries of pharmaceutics, foodstuffs, cosmetic and daily chemicals . With Taiwan's EVIEW touch screen and Taida's PLC control system employed, convenient, visualized and reliablenon-touch operationof the machine is effected compact design and auto tube feed. Driving part fully-closed.

Tube feeding, marking identification, filling, hot air sealing, code printing, trimming and ejecting out the tube conducted by automatic systerm.

Tube feeding is conducted pneumatically,accuratly and reliably. Auto picketage effected by photoelectric inductance. Easy adjustment and dismantling .

Intelligent temp.control and cooling system makes operation easy and sealing reliable. With easy and quick adjustment, it is suitable for using multiple kinds of soft tubes for filling.

The part contacting materials is made of 316L stainless steel, clean, sanitary and conforming to CMP . With safety device, the machine is shut down when the door is opened. and filling carried out only with tubes fed.

| Filling volume | 5-250ml(tube) |

| Filling accuracy | ≤±1% |

| Capacity | 1800-2400(tubes/h Adjustable) |

| Tube diameter | 10-50mm |

| Tube length | 210mm (Max. Length) |

| Hopper volume | 40 L |

| Power | 380V/220V(Optional) |

| Air pressure | 0.5-0.7MPa |

| Equipped motor | 1.1 KW |

| Hot air | 3.0KW |

| Dimension (L×W×H): | 1900×1000×1950mm |

| Weight: (Approx) | 850kgs |

| Packaging Detail:WOODEN BOX AND OTHER |

| Delivery Detail:30DAYS |