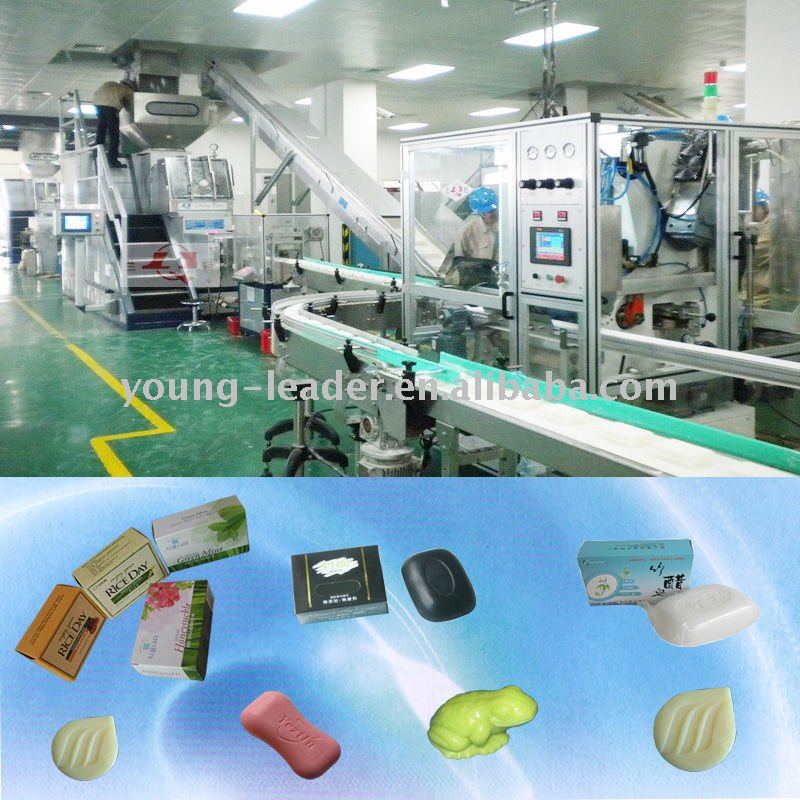

soap machinery line

| Machine Type:Granulator | Product Type:Soap | Place of Origin:Shanghai China (Mainland) | Brand Name:oem |

| Model Number:soap machinery |

1. the equipment and machinery for vacuum drying unit model FT3000S for toilet and translucent soap are the fruit of 18 years' study on this specific field by LIMAC.

2. the experience attained through fabricating of the equipment and machinery for 128 sets of soap vacuum drying units makes the quality and quantity of such equipment being delivered by a company top in china.

3. Model FT/3000S vacuum drying unit for toilet soap and translucent soap makes the translucent soap pellets look more crystal;the translucent soap pellets top quality;

4.a perfect improvement of the machine,you will get much finer,much translucent ,much uniform soap pellets from it.

Equipment List

5.Equipment List

Item | Equipment Name | Equipment type | Qty | Power Consumption |

1 | Mixer | 3000S-600Z | 1 | 2*18.5KW |

2 | Three Roller Mill | 2000S-405-1000 | 1 | 22KW |

3 | Vacuum Plodder | 3000S-DR | 1 | 2*37KW |

4 | Refine-Plodder | 3000S-DRVP | 1 | 37KW+30KW+3KW |

5 | Billet Cutter | 2000S-XQKI-300 | 1 | |

6 | Press With Freezing Dies | LDX-700 | 1 | 7.5KW |

7 | Glycol Chiller | LX/A500S | 1 | 8KW |

8 | Glycol Chiller | SP3-H-15FGD | 1 | 11.2KW |

9 | Belt Conveyor | 2000S-400 | 2 | 1.1KW+1.5KW+1.1KW |

10 | Soap Dies | Copper Dies | 2 |

6.Technical Parameters

Item no.1: Mixe

Mixer Weight:350kg/times,Different speeds,

1thAgitators22r/min,2thAgitators36r/min

SEW Tow-speed reducer,Agitator diameter:600mm.

Capacity:250-350 kg/batch

Material Used: Frame ---Q235 good quality carbon steel, the part reached by soap

noodle is made with stainless steel.

7.Three roller mill

Item no.2: Three roller mill

Roll diameter:405mm;Roll' working length:000mm;apacity: 3000kg/h

Material Used: frame- Cast iron, roller-high Chrome alloy, hard wearing

8.Vacuum Plodde

Item no.3:acuum Plodder

Roll diameter:350MM;ooling water temperature;5 max,

Worm speed:th 18r/min,2th 5-18r/min.Touch screen,

Capacity: 3000kg/h

Material Used: fame-Q235 good quality carbon steel, 80 splicer made, the part

reached by soap noodle- stainless steel. It adopts hard tooth surface reducer

with vacuum pump. Screw body is with cooling jacket. The exit is with heater device.

9.Refine- Plodder

Item no.4:Refine- Plodder

Roll diameter:350MM;ooling water temperature:5Cmax,

Worm speed:th 18r/min,2th5-18r/min.Touch screen,

capacity: 3000kg/h

Material Used: fame- cast iron, rail-wearable steel, some parts-45# steel and copper alloy

10.Billet Cutter

Item no.5: Billet Cutter

Chain style,adopt Air Motor; The Speed Same As the Plodder

11.Press With Freezing Dies

Item no.6 Press with Freezing Dies

Stroke /min:10-50/min,Soap tablet wt:720kg.

Lower die rocking angle:0 degree.Touch screen.

Temperature of frozen dies:10~ -25°C;

apacity:1500kg/h

12.Glycol Chiller

Item no7 Glycol chiller

3500kca1/h at lowest temperature.

Item no.8 Glycol chiller

25-5°C,40600kca1/h at lowest temperature.

13.Belt Conveyor

Item no.9 Belt conveyor

Belt width:40mm;Fin pitch:250mm;

elt speed:32-40m/min;EW Tow-speed reducer,

Two sets /6 cups

14.Soap dies

Item no.10 Press with Freezing Dies

All stamping dies for toilet soap "Safeguard" that is produced

in China by Proctor & Gamble are exclusively to be fabricated

by LIMAC Machinery Works Corporation, Lanzhou, China.

The stamping cavities are machined by high-precision 5-mandrel

machining center.

15.Equipment picture Lis

| Packaging Detail:wood case |

| Delivery Detail:30/days |