small capacity gypsum board making machinery(500000 sqm)

| Place of Origin:Shandong China (Mainland) | Brand Name:YUANTENG | Model Number:YT-GB | quality:good |

1. Production scale:

Annual productivity:500000 to 50 million sqm

2. Board specification& quality standard:

thickness: 8--20mm, length: 2400--3600mm, width: 1200--1250mm

3. Main raw material and fuelconsumption:

| gypsum powder | 6.8 kg/m2 |

| paper | 0.45 kg/m2 |

| gypsum board adhesive | 0.035 kg/m2 |

| foaming agent | 0.008 kg/m2 |

| white glue | 0.005 kg/m2 |

| power | 0.3 kwh/m2 |

| water | 4.5-4.8 kg/m2 |

| heat consumption | 3800 kcal/m2 |

| coal (heat value based on 5500 kcal/kg) | 0.69kg/m2 |

| natural gas (heat value based on 8500 kcal/kg) | 0.45 m3/m2 |

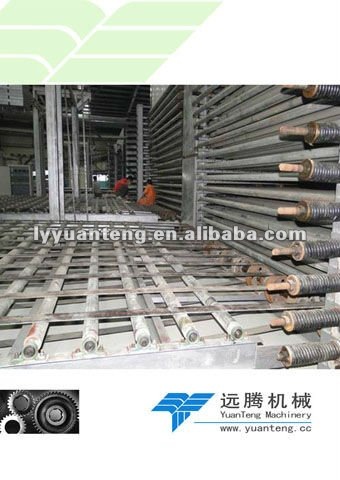

4. Main systems of gypsum board production line:

Dosing section--- forming section--- drying section--- cutting and stacking system--- electrical control system

5. Production method of gypsum board:

Gypsum powder, water and a variety of additives, measured by the automatic and accurate calculation respectively, through the continuous, automatic transmission system into the blender. Stir mixture into a homogeneous slurry, scatterable forward to the continuous movement of gypsum board of surface paper, the process forward, after shock slurry absorbed gradually disperse cloth, arrived at the molding stations, and the back of gypsum board paper composite, by extrusion-molding machine. The next size cardboard was fully encapsulation, and squeezed into the very rules plate. The plate production line in a row to strictly control the speed of the stability to continue moving forward, after about 5 minutes, gradually forming a certain intensity, shape the rules of wetlands gypsum board, the precise control of the cut, set by the size of precise cut into veneer. Veneer programmed by the system of orderly, turned face, entered the dryer, in strict control of the drying system. Lose the board absorbed water. Plate from the dryer and the production line forward the process of gradually cooling down. After again turned face, plate every two positive side compoosite, then cutting the boards into needed sized with cutter grinding. Automatic of the stacker, stacking neatly into the rules of storage products.

| Packaging Detail:wooden boxes,containers |

| Delivery Detail:90 days |