Slurry Dewatering Machine Water Recycling Thickener

| Type:Mining Thickener | Condition:New | Application:water recycling, waste water treatment | Motor Type:AC Motor |

| Power(W):1.1-7.5 | Production Capacity:1.2 | Place of Origin:Shandong China (Mainland) | Brand Name:xinhai |

| Model Number:GSNG | Dimension(L*W*H):5m*6m*4m | Certification:CE, ISO 9001 | Warranty:360days |

| After-sales Service Provided:Engineers available to service machinery overseas | tank:steel | foundation:steel structure | feeding density:30% |

| discharging density:55-70% | usage:ore dewatering, waste water recycling |

Slurry Dewatering Machine Water Recycling Thickener

Introduction

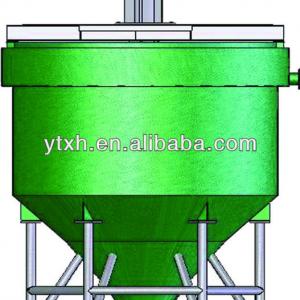

Thickeners are used for dewatering slurries of either tailings or product. This type of thickener's height is far more bigger than diameter, and has vertical bucket cone type in appearance. It is suitable for dealing with large capacity and light density products.

Features

- The height is far more bigger than diameter, vertical bucket cone type in appearance.

- Slender body, flocculant is added in the process of concentrate, accelerate the particle settlement and dewatering process.

- It has the following features: less time of concentration, small area taken, high automaticity, low power consumption, high efficiency.

Application

The machine is suitable for dealing with large capacity and light density products. Mainly used for condensing concentrate and dewatering the tailings. It can be also used for condensing and cleaning the pulp with solid particles in coal, chemical, building materials andsewage treatment system.

Working principle

This thickener consists of round thickener and harrow scraping machine, the solid particles suspend in thickener settling by gravity, the pulp in the upper turn into clean water, so that the separation can be realized. Slime that sediment in the bottom of the thickener is discharged by the harrow scrapping continuously, and clean overflow from the upside.

Technical parameters

| Model | Diameter of the thickener (mm) | Depth of the thickener (mm) | Settlement factor (m2) | Capacity (m³/h) | Motor power (kw) |

| GSNG-3 | 3000 | 4404 | 21 | 60-70 | 1.1 |

| GSNG-6 | 6000 | 8810 | 85 | 210-260 | 2.2 |

| GSNG-9 | 9000 | 13500 | 190 | 340-470 | 4 |

| GSNG-12 | 12000 | 17500 | 340 | 570-770 | 5.5 |

| GSNG-15 | 15000 | 19080 | 530 | 660-880 | 6 |

| Packaging Detail:The main machinery is in nude packing,and spare parts in Wooden or steel box standard export packing, suitable for long distance delivery. |

| Delivery Detail:30days |