Sintered porous metal filter tube

| Place of Origin:Henan China (Mainland) | Brand Name:Meilin | Model Number:msw1-msw200 | Usage:Variety of uses |

| Type:Filter Elements,high | Material:Metal,316L,304 | Hole Shape:Diamond | Filter Rating:1-200um |

| Thickness:1-5mm | Length:1200mm | Width:1000mm | Function:filter |

| Filtration range:1-200um | Thickness range:1-5mm | Diamter:greater than or equal 10mm | Color:Silver gray |

| Use:Solid,liquid,gas | Structure:multilayer layers | Shape:Round |

Chinaprofessional manufacturer of Sintered porous metal filter tubewith ISO approved

We have various types of Sintered porous metal filter tube,in order to give you a responsible quotation, you can inform us the following informations :

1. The drawing of the filter

2.The filtration you need

3. The material you want

4. The diameter of the product

5. The Thickness of the product

1. Sintered porous metal filter tubeintroduction:

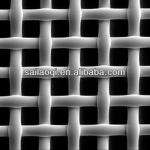

Sintered porous metal filter tubeis the application of perforated plate sintered wire mesh. it is made of sintered mesh after cutting, precision welded.

To ensureroundness and flat, stainless steel sintered mesh filteris sintered after using rolling seam welding process and the method of correction weld, it can make the overall look more beautiful.

2. Sintered porous metal filter tubeadvantages:

1.Strength: As the fourth layer do support, with high mechanical strength and compressive strength.

2. Easy to clean: As a result of surface of the filter material, having means for cleaning characteristics, especially suitable for backwashing.

3. Easy processing: suitable for cutting, bending, stamping, drawing, welding and other processes.

4. High temperature: 480°Ccan withstand high temperatures.

5. Corrosion resistance: As a result of SUS316L, 304 materials, the corrosion resistance.

6. Filtration: Filtration range of 1μm-200μm, has a reliable filter performance.

7. Stability: Because there is one layer to do to protect the screen, plus solid melting diffusion sintering process which make filters is not easily to deform.

3. Sintered porous metal filter tubeapplications:

Used in water treatment, pharmaceutical, chemical, food, beverage, oil filtration and etc , it could be filter mesh, filter element, filter cartridge, filter disc and etc.

4. Technical Parameters

| Type | Nominal Accuracy (μm) | Gas Permeability (L/mil•dm² • 1000Pa) | Bubble Pressure |

| MSW1 | 1 | 180 | 5300-6000 |

| MSW2 | 2 | 240 | 4300-5000 |

| MSW5 | 5 | 260 | 3000-3700 |

| MSW10 | 10 | 310 | 2700-3300 |

| MSW15 | 15 | 350 | 2000-2600 |

| MSW20 | 20 | 450 | 1800-2300 |

| MSW25 | 25 | 620 | 1400-1900 |

| MSW30 | 30 | 690 | 1200-1700 |

| MSW40 | 40 | 420 | 1000-1500 |

| MSW50 | 50 | 850 | 900-1200 |

| MSW70 | 70 | 900 | 700-1100 |

| MSW100 | 100 | 1080 | 650-1000 |

| MSW150 | 150 | 2600 | 500-800 |

| MSW200 | 200 | 2800 | 450-600 |

5. Abouts Us

Xinxiang Meilin Hydraulic Accessories CO., LTD, which was built in 1984, is located in the southern suburd of Xinxiang city. We are away from Holland railway for 200 meters in the south, and in the north away from Beijing-Guangzhou line railroad for 1 km, so we haveconvenient transportation.

In 2010 Our company introduced advanced casting and sintering equipment, and sevetal international advanced testing equipments, to ensure the accuracy and quality of the products. All kinds of filters, die casting, sintering products strictly in accordance with ISO9001:2008 quality management system.

6.Packaging & Delivery

1. Port: Qingdao, Tianjin or as request

2. Delivery: 7-15 workdays after the down payment, and according toorder quantity

3. Packaging:Bubble wrap inside, woodencase outside

| Packaging Detail:Bubble wrap inside, woodencase outside |

| Delivery Detail:15 days after the down payment,and according to order quanitity |