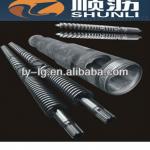

single screw barrel of injection and extruder machines

screw barrel, 1.38 CrmoALA Material, 2. Nitriding Depth: 0.5~0.7mm, 3. High Qulity Base Material, 4. Screw Barrel for injection - details see: https://www.machineto.com/single-screw-barrel-of-injection-and-extruder-machines-10335253

| Place of Origin:Zhejiang China (Mainland) | Brand Name:LiJing | Model Number:LJ- | Steel Material:Alloy-steel of High-Quality |

| Screw Diameter:15mm-300mm | Technical Index:30g-25000g |

screw barrel

Detailed Product Description

1.single screw and barrel

2.High Quliaty Base Material

3.Processed to drawing or to your request on output&raw materia

Single screw and barrel are used in extrusion process. Product with carefully choosing the design (barrier, maddock, spiral).

Single Screw and Barrel Ranges:

| Screw Diameter | 15mm-300mm |

| Screw Length | L/D ratio 15 - 46 |

Material

1 38CrMoAIA(JIS SACM645)

2 9Cr18MoV

3 42CrMoV(AISI 4140)

4 41CrA1Mo7

Heat treatment

- Nitriding treatment

- Electroplated hard chromium coating

- Spray coating anticorrosion

- Wear resistant bimetallic coating

| Technical Parameter |

| Hardness of Nitriding | Hv900~1000 |

| Deepness of Nitriding Layer | 0.7mm-0.9mm |

| Surface Roughness | Ra 0.4μm |

| Hardness of Bimetallic Alloy | HRC 55-62 |

| Deepness of Bimerallic Alloy | 1.5~2.0mm |

| Screw straight tolerance | 0.015 mm/m |

| Special treatment | Carbide coating on flight |

| Deepness of Titanizing Layer | 0.05~0.10mm |

Process

- Laser Coating Tungsten Carbide

- PTA Melt-Welding Alloy

- Centrifugal Mould Bimetallic Alloy

- Advanced nitrogen oozes handicraft

- Vacuum Quenching

- Titanizing

- Nickel Plating

- Chorme Plating

Our screw and barrel can ensure high performance and low energy consumption of extruder and Injection molding machine.

What's more, we can supply professional screw and barrel to your order

| Packaging Detail:wooden case |

| Delivery Detail:30 days after order confirmed |