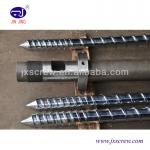

Single extruder screw barrel for film blowing extruder machine

| Place of Origin:Zhejiang China (Mainland) | Brand Name:OSD | Model Number:OSDXZ326-66 | Desigh:Single extruder screw barrel for film |

| Feeding Zone Groove:new type grooves | Application:PE/HDPE/LLDPE/PP and other raw material | Alloy material:Wc/Co, Ni, Mo, and other hard material | Nitriding depth:0.5-0.8mm |

| Packing:AA Grade Woodencase | Nitrided hardness:HV850-1000 | chromium-plating depth:0.025-0.10mm | alloy hardness:HRC56-65 |

Single extruder screw barrel for film blowing extruder machine

| Diameter | Φ15mm-350mm | Designing | Screw structure and compression ratio can be designed according to different products & different output re quirement. |

| Materials | 38CrMoAlA (JIS SACM645) SKD61 | Application | PE , PP , HDPE , LDPE , LLDPE , PVC ...... |

| Nitride Case Depth | 0.5mm-0.8mm | Technology | 1)Longer time Gas Nitriding treatment 2) Special corrosion & abrasion alloy (bimetallic) 3)Tungsten carbide 4)Cobalt base alloy 5)Stainless steel 6)GH113 nickel based alloy |

| Nitride Hardness | 950-1020HV | Packing | Wrapped up by film in wooden case |

| Nitride Brittleness | ≤Grade One | Payment Term | T/T , L/C , WESTERN UNION |

| Surface Roughness | Ra0.4um | Delivery Term | 25 working days |

| Screw Straightness | 0.015mm | Port Departure | Shanghai/Ningbo |

| Alloy Hardness | HRC58-62 | Min. Order | 1 set |

| Alloy Depth | 0.5mm-0.8mm | Guarantee | Common Nitrided:2.5-4years Bimetallic: much longer lifetime |

| OSD ADVANTAGES | 1.Advanced Nitriding Technology 2.Duplex metal Spraying Technology for high corrosion and abrasion resistance 3.We use special alloy powder being sprayed and welded on the screw's ridge, and use different alloy and welding methods for the screw of different functions. 4.Fast and on time delivery . 5.Longer lifetime for the screw barrel. | ||

Technological Process:

Blanking→Rough Machining→Quenching & Tempering →Semi Finishing Machining→Finished Product→Detecting→Nitring/Alloy Processed →Finish Machining

For good plasticizing effect, we have different design of screw barrel to meet customer's demand:

gradual type, mutant type, wave type, barrier type, double screen type, shunt type, separation type, exhaust type, pin type, double-head type, multi head type etc.

Single extruder screw barrel for film blowing extruder machine

have following features :

- The screw adopt barrier type mixing zone.

- The barrel feeding zone is groove feed bush and made of hard alloy.

- It results in higher output rates, homogeneous plasticizing and less material slippage.

- Bi-metallic screw&barrel can be provided for two-three times more lifespan than nitrided screw&barrel.

Features:

- Easy operation

- Optimum performance

- Durable

- Low power consumption

- Corrosion resistance

About O.S.D :

- Our Strength:We have an experience of more than 20 year of manufacturing and designing Plastic machines, varied Screws and Barrels and spares. We concentrate on improving quality, updating design and enhancing service.

- Our products:Screws Barrels for Injection, Extrusion, and Blow Molding applications; relevant accessories(such as die head, gearbox, filter screen changer and so on); plastic processing machinery.

- Location advantage:located in China's Screw Town - Jintang Town in Zhoushan City, near toNingboPortandShanghaiPort.

- Market areas: global sales network reaching South America, Eastern Europe, Southeast Asia, Africa, Oceania and the Middle East.

- We promise: We assure the customer benefits, We provide competitive price, We Emphasis On Cooperation.

| Packaging Detail:AA grade wooden case |

| Delivery Detail:25 working days |