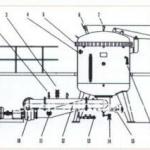

shanghai jet Dyeing Machine

1 Low dye tension, 2 Jet nozzle, 3 Wide range of speed-adjusting - details see: https://www.machineto.com/shanghai-jet-dyeing-machine-10278270

| Condition:New | Automatic Grade:Automatic | Place of Origin:Shanghai China (Mainland) | Brand Name:PDM |

| Model Number:ECL | Voltage:380V/50Hz | Certification:UKAS,ISO9001 | Warranty:01year |

| After-sales Service Provided:Engineers available to service machinery overseas |

I Characteristic

| Advanced multi-function high pressure fluid dyeing machine, mainly used in the weaving cloth of natural or synthesize fiber, string spin fiber(T/C,T/R,T/W )and dye of super-thin fiber ,compound fiber and pre-treatment with high extra value. |

II Standard structure

| 1 Produced highly erosion proof stainless steel materials for the main part contacting width the dye liquid and the machine body |

| 2 High efficient stainless steel centrifugal pump, transducing soft setup control for the main pump |

| 3 Transducer control and motor drive for the lift roll |

| 4 Pneumatic control heating and cool valve with temperature control function |

| 5 Pressure increase and decrease system for the machine body. |

| 6 Tube type heat exchanger of high efficiency |

| 7 Pneumatic valve of water entry, drain, and overflow cleaning. |

| 8 Level indicator with level sensor |

| 9 Material feeding pump, valve, and stirring function fit with color bucket. |

| 10 Full auto master control power box and controller. |

III Product features

| 1 Low dye tension: equipped with the cloth guide roll with frequency conversion motor, for cloth movement assistant. High efficiency with loose fabric ,even dyeing :the perfect combination of reaming reel and nozzel of the master vessel(double jacket type),realize the smooth fabric flow of the weave of material of any type .The appearance and the double jacket structure eluded effectively the uneven dye and friction prints |

| 2 Jet nozzle:the clearance of it can be regulated according to different fabrics and its technique to reach the best effects of dyeing |

| 3 Wide range of speed -adjusting :by using the cloth guiding square box and the shocking point of machine rail to let piece goods being arranged and piled regularly even under high speed running .assissted by the control of the lift motor,the cloth range is at 150~600m/min adjustable |

IV Accessories

| 1 Layout plaiter coupling accessories |

| 2 The 2nd water, and the 2nd discharge |

| 3 Dosing control with precision flow control device |

| 4 Second service tank with individual feed pump ,valves ,string function |

| 5 Seam detector |

V Technique Data of accessories

| Constant liquor ratio | 1:6~7 |

| Maximum working temperature | 140°C |

| Maximum working pressure | 3.8Mpa |

| Heating rate | 20°C~130°C average 5°C/min (dry saturated steam pressure at 0.7Mpa) |

| Cooling rate | 130°C~80°C average 2.5°C/min (cooling water at 0.3Mpa,25°C) |

VI Model

Type | No. of Tubes | Total Power | Dimensions | ||

| L(mm) | W(mm) | H(mm) | |||

| ECL-6-250 | 1 | 23 | 10500 | 1570 | 2900 |

| ECL-6-500 | 2 | 43 | 10500 | 2270 | 2900 |

| ECL-6-1000 | 4 | 84 | 10500 | 5000 | 2900 |

| Packaging Detail:bare machine package |

| Delivery Detail:30~60 working days |