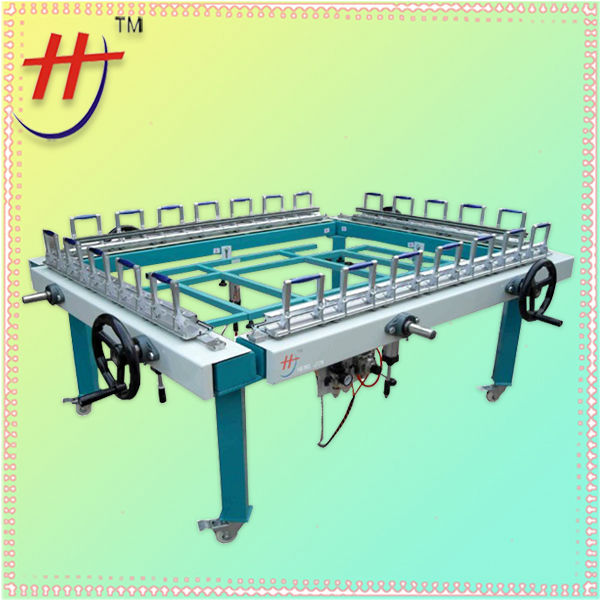

semi automatic double chuck silk screen stretching machine

| Condition:New | Type:screen stretcher | Automatic Grade:Semi-Automatic | Place of Origin:Guangdong China (Mainland) |

| Brand Name:HENGJIN | Model Number:HJ-1200 | Voltage:220V | Power(W):20W |

| Dimension(L*W*H):1600*1300*800mm | Weight:150kg | Certification:CE | Warranty:1 year |

| After-sales Service Provided:Engineers available to service machinery overseas | Pre-pringing equipment:Double chuck silk screen stretching machine | Max extension area:900*1200mm | Mini extention size:adjustable |

| Max Tension:0-40N | Ave Tension:±1 | Single Size Max Extention stroke:150mm |

HJ-1200 semi automatic double chuck silk screen stretching machine

1.manufacturer in Dongguan, Guangdong

2.Max stretcher size:900x1200mm

3.easy operate, economic

| Item Number | Max Extention Size(mm) | Mini Extention Size(mm) | Max Tension (N) | Ave Tension (N) | Single Size Max Extention stroke |

| HJ-1200 | 900×1200 | Adjustable | 0-40 | ±1 | 150mm |

Applied Rang

Applied to various types of screen plate of the drawing, particularly suitable for making color printing screen, high-precision single-sided circuit board

Main Performance

1)Crossbeam is made of 12x 80 special square tube, the tension is up to 50N. The crossbeam can not transformation, although it is stronger extension.

2)In it installed Sliding Plate,4 sides of Crossbeam is moveable, Contraction agile and convenient.According to the size of screen frame to adjust the extention area, and Efficacious save the mesh.

3) There are there style chuck to Choice:

- Steel chuck is made of special extention chuck, the base pull board of chuck is made of 4-5cm thickness steel bended and welded, then endure long –time strong tention.

- Single Aluminium chuck is mede of aluminium alloy sepcial mold and one time to finish,higher accuracy,no slide mesh, carry the mesh is stable, can adjust the degree of tightess automatic.

- Dual-use high-quality aluminum alloy aluminum chuck one-time special mold molding, dual chuck control,no slide mesh, can not hurt meshe and can not quit mesh.

4)Chuck pad attached to the import of rubber, not falling, not to hurt the meshand can not quit mesh.

5)Imported from Taiwan worm drive gear box are connected by gears, rack and linear bearings madetravel guide, the chain of transmission has changed the traditional way, this design tension more uniform, higher accuracy, netting more portable.

6)Matching 4 pcs synchronous tip mesh cylinder and sure the quality of mesh.

7)Surface temperature electrostatic spray machine, with corrosion resistance, wear resistance, difficult to aging and so on.

Construction

| Structure Division | Item | The name of Parts | Construction Explain |

Basic Structure | Structure | Profile | Vertical |

| Rack | SS41# | Welding,Surfacing Handle | |

| Clamp Mesh | Chuck | Mold production | |

| Pedestal | Truckle | 2.5 inch | |

Main Body | Crossbeam | 120×80 Square Tube,Thickness 4mm | |

| Cover Plate | Thickness 4mm | ||

| Triangle | Thickness 4mm | ||

Pneumatic System | Pressure | Piezometer | |

| Tip mesh System | Pnematic | 40×75 Cylinder | |

Tension System | Hand Wheel | ||

| Worm Wheel | Worm Wheel positive speed gearbox | ||

Tooth Box | Gear rack | 20×25×240 | |

| Straight ling Bearing | LM20uu |

| Packaging Detail:Polymer wooen case with protective film |

| Delivery Detail:3-5 working days |