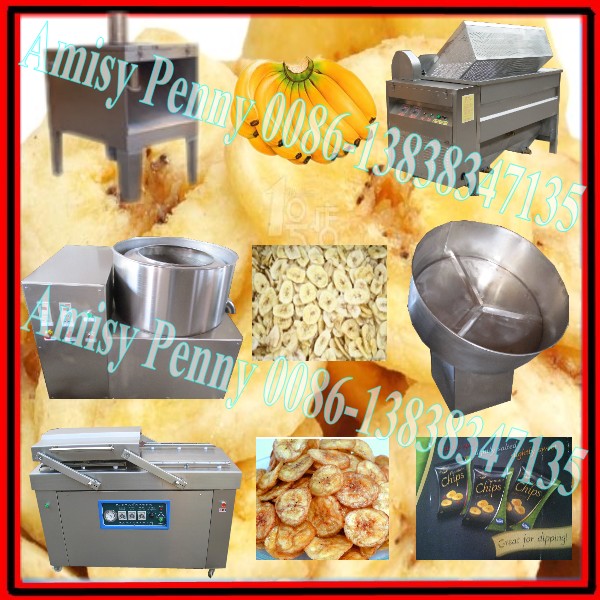

semi-automatic 100kg/h fried plantain chips machine/plantain banana chips processing line

| Condition:New | Place of Origin:Henan China (Mainland) | Brand Name:Amisy | Model Number:AMS-PC100 |

| Type:Cutter | Voltage:380V | Power(W):21kw | Weight:1300kg |

| Dimension(L*W*H):2500*1300*1400mm | Certification:CE | Warranty:one year | After-sales Service Provided:Engineers available to service machinery overseas |

| products:plantain chips potato chips line |

Banana plantain chips making line/potato chips production line

Introduction:

the fried plantain chips production line and potato chips production line is semi-automatic food processing line which is very popular all over the world as snacks. the two production line can share to use many machines. Buying a potato chips line, and adding a plantain chips cutting machine, then you can also make plantain chips,banana chips.

1. plantain banana chips line

the plantain banana chips line is to make fried plantain chips, banana chips. the processing is as following:

plantain chips cutting machine---plantain chips frying machine--deoiling machine--flavoring machine--packing machine.

a. Plantain chips cutting machine is to cut the banana plantain chips into thin pieces.

b.Frying can reduce the moisture to 2% and get the crispy plantain chips.

c.Deoiling machine is to remove off the oil on the chips after drying.

e. Flavoring machine is to add kinds of flavor to the plantain chips.

f. Packing machine is to package the chips into bags.

Specification:

2. potato chips production line

As a kind of worldwide popular snack, fried potato chips producing is certainly in large demand. Amisy food machinery supplier offers several potato chips production lines which contains fully automatic plant and semi-automatic plant. Our semi-automatic plants consist of 8 independent machines with the capacity of 30kg/h, 60kg/h and 150kg/h.

AMS Fried Potato Chips Processing Procedure

Fried potato chips production the flowchart includes the following steps:

Fresh Potato—washing &peeling—cutting—blanching—dewatering—frying—de-oiling—flavoring—packing.

1. Washing and peeling is the first step. Potato washing and peeling machine is specially designed and hardly no damage to potatoes . Then it discharges potato strips automatically.

2. Equipped with sharp blades, potatoes are cut uniformly and evenly.

3. Blanching is to wash out the starch on the surface of potatoes and avoids the potato chips sticking.

4. Then the dewatering step is to help reduce moisture and make them easy to fry.

5. Frying can reduce the moisture to 2% and get the crispy potato chips. We offer the pure peanut oil and change the continuous working oil every 8-12 hours. The frying process should be less than 4 minutes.

6. The fried potato chips are placed on the draining oil belt to fish out the spare oil.

7. The flavoring machine is used for seasoning the fried potato chips. Whichever flavor is needed totally depends on yourself.

8. Vacuum nitrogen packaging machine is ready here to ensure the high efficient packing. As fried potato chips are fragile, the nitrogen is necessary to keep food fresh, tasty and without damage.

Specificaton:

| Packaging Detail:wooden case packing |

| Delivery Detail:one week after deposit payment |