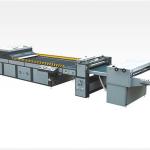

Security Labels Hotmelt Coating Machine

| Type:Coating Machine | Condition:New | Application:Food,Beverage,Commodity,Medical,Machinery & Hardware,Apparel,Textiles | Automatic Grade:Automatic |

| Driven Type:Electric | Voltage:As per client's requirement | Packaging Type:Case | Packaging Material:Plastic,Wood |

| Place of Origin:Jiangsu China (Mainland) | Brand Name:HF | Model Number:HF-A80 | Dimension(L*W*H):8400*2700*2350 |

| After-sales Service Provided:Engineers available to service machinery overseas | Unwinder type:Lifting Unwinder | Rewinder Type:Lifting Rewinder | Die Coater type:Slot Die Coater |

| EPC:1 SET | Unwind diameter:1000mm | Rewind diameter:1000mm | Unwinder:2 SETS |

| Rewinder:1 SET |

Security Labels Hotmelt Coating Machine

This Machine is available to see running machine when you come China.

1.Application

Mainly for producing Adhesive Label,Double Side Tape,Foam Tape,Duct Tape,Kraft Paper Tape,Masking Tape,

Fiber Tape,Fabric etc.

2.Main Feature:

(1)The design of extending the distance between 2nd Unwinder and Laminating,makes the correction function

much better.

(2)Unwinders are all adopt EPC.

(3)Unwinder with the function of lift and down materials Electrically.

3.Flow Chart:

Back to Wet is a extra function,you can select according to you requirement.

4.Technical Parameters

| Model | HF-A80 |

| Coating Width | 400-2500mm |

| Coating Weight | 10-200g/m2 |

| Coating Speed | 80m/min |

| Unwind Diameter | 1000mm |

| Rewind Diameter | 1000mm |

| EPC | 1 SET |

| Length | 8400mm |

| Height | 2350mm |

5.Major technical parameters of the main production line

(1). Material used: hot melt pressure-sensitive adhesive

(2). Effective coating width: 1100mm

(3). Roller width: 1200mm

(4). Coating glue weight: 10~50g/m2, (by 20g/m2,±1g)

(5). Max.Coating Speed: 80M/Min

(6).Max.Mechanical Speed: 100m/Min

Ifglue coating less than 20g/m2, the maximum production speed is 200M/Min

(7). Glue melting speed of the tank: 300kg/h EVA 165°C 3000CPS

(8). Unwinding style: adopts of center shaft single work position and center unwinding 3"

Magnetic power brake, tension system adopts Japan Mitsubishi constant tension controller .

(9). Maximum diameter: unwinding is Φ1200mm, rewinding is Φ1000mm

(10). Electrical control method of the complete machine:

PLC controller/ Siemens s7-300,10”human-machine interface operation

(11). Temperature control method of the hot melt glue tank:

adopts Japan Panasonic temperature controller, digital display with temperature

exceeding alarm function, PID Intelligent adjustment, temperature control scope: 0-250°C,

(12). Specification of the glue melting tank and its extruding amount:

adapts Al-alloys to casting and forming, divided into 3 layers: upper, middle and lower.

The inner wall has coated with a layer of Teflon for preventing of sticky. Maximum

extruding amount is 300kg/h and the maximum volume is 600L, heating power is 45kw.

(13). Driving motor: AC frequency converter motor/ gear reduction motor/ 3 phase

asynchronous motor (Taiwan Chengbang, Shanghai Haozheng series)

(14). Frequency converter:

Digital AC vector control frequency converter. Japan Yaskawa made

(15). Paper core roller: Unwinding adopts of 3” inflatable style core.

(16). Power supply: three- phase, 380V 50Hz.

(17). Input power: Installed power rating 120kw (By normally using is 70kw)

(18). Cooling water: temperature is 16-25°C, flex is 8 cubic meter/hr. , water pressure

is 2kg/square centimeters (will be prepared by demanding company)

(19). Compressed air supply: Air pressure is above 5kg pre square centimeters,

(Will be prepared by demanding company)

(20). Heating method of the glue melting tank: Electric heating.

(21). Heating method of the die slot heads and the glue transfusion tubes: Electric heating.

6.Client's comment on our machine:

Something need clarify first:our company move from Rui'an to Wu'xi,company name change from "Rui'an Haozheng Hot Melt Equipment Co.,ltd" to "Wuxi Haofan Hot Melt Equipment Co.,ltd",Then Machine model change from "HZ" to "HF",Pls notice.

(1)Year 2009

Finally Mr.Mayur bought a HF-A180 in year 2009 with the introduce of our old clients-Mr.Mahesh.

Mr.Mahesh Bought the Model HF-A60 which is simliar with HF-A50,will not show in website from now on.He also bought model HF-A80.

(2)Year 2013

Hereby we show our sincerely to our clients,thank you for your long term support!We will try our best to Provide higher quality machine as return of your kindly support.

| Packaging Detail:Bubble&Stretch Film&Wood |

| Delivery Detail:60 days after receive deposit |