SBM Clay processing plant,Vibrating Screen,screening machine,CE with high quality

| Condition:New | Type:Circular | Application:Ore | Place of Origin:Shanghai China (Mainland) |

| Brand Name:SBM | Model Number:YA Series | Power(W):5.5-30KW | Weight:2.34-12.35t |

| Certification:ISO9001:2008,CE | After-sales Service Provided:Engineers available to service machinery overseas |

SBM Clay processing plant

As kind of important raw mineral materials, clay mine’s crushing and grinding is extremely important in the whole clay mining processing plant. There will be both stationary crushing screening plant and mobile or portable plant provided for your mining.With the ability to maximize product output, our machineries feature high production rates, low operating costs and simplified state of the art mainframe.

Clay crushing and grinding equipment

There is also complete clay mining crushing plant provided for you, such as stationary plant, portable crusher plant and mobile crushing screening plant, etc. In all these plants, we can install screening equipment and feeders according to your requirements.

There is whole clay grinding plant which can be designed and improved based on your requirements. In the clay grinding plant, there will be also powder classifier, cyclone collector, decelerator, blower, clay crusher, elevator, feeder and control cabinet.

Clay processing flow

Clays usually are transported by truck from the mine to the processing plants, many of which are located at or near the mine. For most applications, clays are processed by mechanical methods, such as crushing, grinding, and screening, that do not appreciably alter the chemical or mineralogical properties of the material. However, because clays are used in such a wide range of applications, it is often necessary to use other mechanical and chemical processes, such as drying, calcining, bleaching, blunging, and extruding to prepare the material for use.

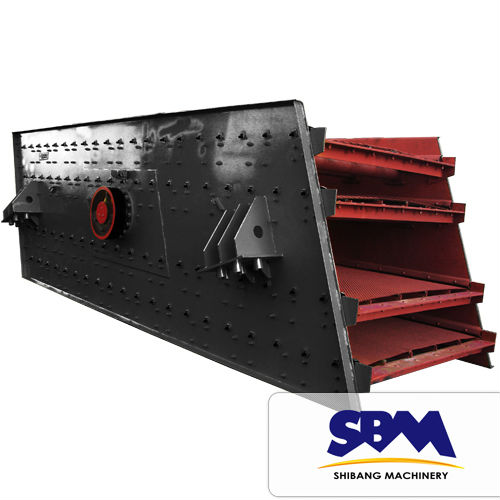

Vibrating Screen

The vibrating screen is a kind of sieving equipment of international advanced level, developed by our company on the basis of carrying on the advantages of traditional screens and absorbing the outstanding technology from abroad.

It is widely used for grading and screening materials in the following fields: minerals, quarry, building materials, water conservancy and hydropower, transportation, chemical industry, smelting and so on.

Vibrating Screen Operating principle:

It adjusts the amplitude by tube-shaped violent vibration screen of eccentricshaft and eccentric blocks. The body moves like a circle, in order to make the materials screened.

Vibrating Screen Specifications:

| Type | Screen Spec .(mm) | Layers | Sieve Pore (mm) | Max. Feed Size (mm) | Capacity (t/h) | Power (KW) | Screen area (m2) | Weight Excluding Motor (t) |

| 2YA1237 | 1200x3700 | 2 | 3-50 | 200 | 7.5-80 | 5.5 | 3.6 | 2.34 |

| 3YA1237 | 1200x3700 | 3 | 3-50 | 200 | 7.5-80 | 7.5 | 3.6 | 3.05 |

| 2YA1548 | 1500x4200 | 2 | 5-50 | 400 | 50-208 | 15 | 6.3 | 5.33 |

| 3YA1548 | 1500x4800 | 3 | 5-50 | 400 | 50-250 | 15 | 7.2 | 6.07 |

| 3YA1848 | 1800x4800 | 3 | 5-80 | 400 | 50-300 | 18.5 | 8.64 | 6.93 |

| 3YA1860 | 1800x6000 | 3 | 5-80 | 400 | 50-350 | 22 | 10.8 | 7.70 |

| 3YA2160 | 2100x6000 | 3 | 5-100 | 400 | 100-500 | 30 | 12.6 | 9.24 |

| 2YA2460 | 2400x6000 | 2 | 5-150 | 400 | 150-700 | 30 | 14.4 | 12.35 |

Note: This specification is just reference, any changes are subject to the products.

| Packaging Detail:Export Standard |

| Delivery Detail:30 Days |