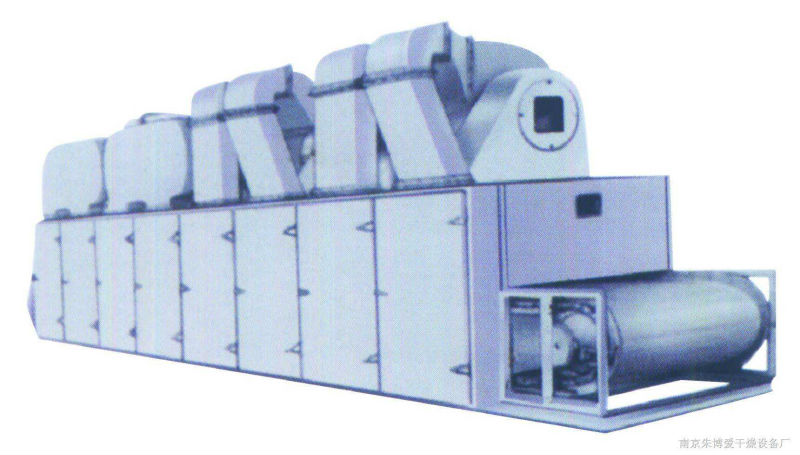

Sawdust made into pellet Belt steel mesh drying equipments

| Condition:New | Type:mesh belt dryer | Place of Origin:Henan China (Mainland) | Brand Name:King State |

| Model Number:DW-1.8*8 | Voltage:280v | Power(W):11 | Dimension(L*W*H):2000X2500X8000 |

| Weight:10t | Certification:ISO9001; SGS | Warranty:12 months | After-sales Service Provided:Engineers available to service machinery overseas |

| Model:DW-1.8*8 | Layers:2 | Width of belt (mm):1800 | Length(m):8 |

| Thickness of your materials(mm):10-100 | Temperature(℃):50-180 | Drying area for 3 layers:43.6 | Drying time(h):0.2-1.2 |

| Evaporation capacity:6-20Kg/ m2.h | Qty of motors:1 |

Application:

Belt dryers are predominantly used in the following industries:

· Chemical Industry

· Pharmaceutical industry

· Food and feeding-stuff industry

· Non-metallic minerals industry

· Plastics industry

· Wood industry

· Ceramics Industry

Main Features of Conveyor Mesh Belt Dryer:

1.Small space to take and low investment.

2.Large output and high evaporation strength.

3.The number of segments can be increased according to the output.

4 it is not necessary to build foundation. You can directly use it after purchasing.

5. Each dryer cell can be individually controlled and the drying.

6. The speed of the conveyor belt can be varied

7. It is used for brittle materials;

Working principle:

1.A Belt dryer / Belt cooler is a device designed for the particularly gentle thermal treatment of product. The wet raw materials are uniformly distributed on the mesh-belt by the material feeder.

2.The mesh-belt generally adopts 12-60 mesh stainless steel mesh and it is drawn by a transmission device and move inside the dryer . The belt, predominantly in horizontal position, carries the product through the drying area which is divided into several sections.

3.In these cells, hot gas flows through or over the wet product and dries it. Each cell can be equipped with a ventilating fan and a heat exchanger. This modular design allows the drying and cooling temperatures to be controlled separately in the different sections. Thus, each dryer cell can be individually controlled and the drying / cooling air flow can be varied in each cell. In addition, the speed of the conveyor belt can be varied what gives an additional parameter for setting of drying time. The cells can be heated or cooled directly or indirectly, and all heating media, such as oil, steam, hot water or hot gas can be used.

Technical parameters:

| Packaging Detail:Nude package for main machines and spare parts will be packed in wooden boxes. |

| Delivery Detail:25-30 days after contract confirmation |