Sawdust dryers/Sawdust dryer for sale/Sawdust rotary dryer

| Condition:New | Type:Rotary Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:GHM |

| Model Number:2.4x20m | Voltage:380V-440V | Power(W):37000 | Dimension(L*W*H):20000x2400x2400mm |

| Weight:55700kg | Certification:ISO9001/CE | Warranty:1year | After-sales Service Provided:Engineers available to service machinery overseas |

| colour:According To Customer Requirements | application:Dry sawdust, wood chips drying | Drum material:Q345 | heat producer:Coal, oil, natural gas |

| Inner Diameter:2400mm | Length:20000mm | Gradient:3-5% | Rotate Speed:3.0(r/min) |

| intake air temperature:<700 | Motor protection grade:50HZ-60HZ |

Sawdust dryers/Sawdust dryer for sale/Sawdust rotary dryer

The sawdust dryer is also known as the hot air pulse dryer and hot air pipe drying machine, which is specially designed for drying the wood chips, sawdust and wood pellets. The sawdust dryer sends the wood chips, sawdust, or the particulate materials to the duct of the dryer. With parallel flow of the hot air, the materials are boiled and fluidized in the barrel. The hot air and the material can fully touch and hit each other to complete the drying process. The sawdust dryer produced by Henan Gude Heavy machinery manufacturing co., LTD . is the optimal drying equipment for the customers among the wood drying equipments. The sawdust dryer can not only dry the fine materials, such as wood chips and sawdust, but also can dry the bulk materials, such as the shavings and wood chips

Application scope of Sawdust dryers/Sawdust dryer for sale/Sawdust rotary dryer

The airflow sawdust dryer is widely used in straw briquette fuel, charcoal machinery, wood pellet fuel, sawdust briquettes and agricultural engineering industries.

Structure of Sawdust dryers/Sawdust dryer for sale/Sawdust rotary dryer

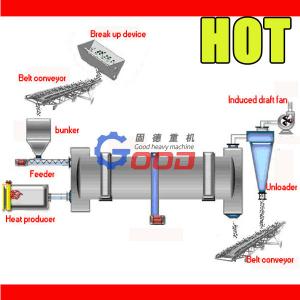

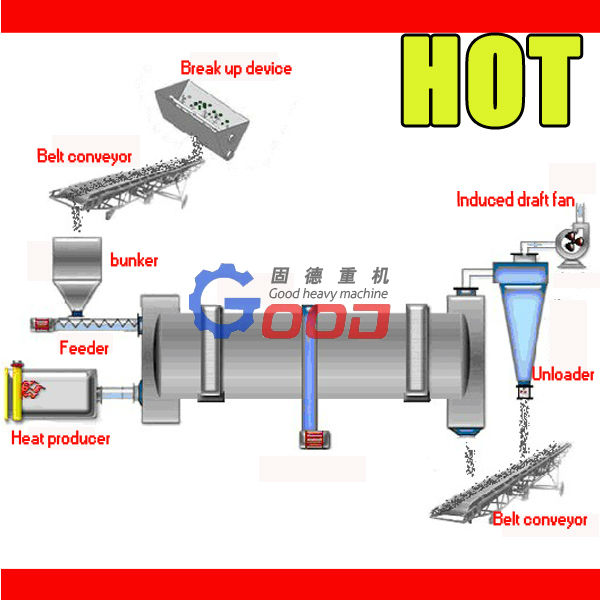

Sawdust dryer is composed of hot stove, feeding port, rotating cylinder, filter cartridges, material conveying pipe, cooling tube and discharging port; rotating cylinder is located in the active roller, which takes low-speed rotation; the feeding port is set between heating furnaces and rotary cylinder, the rotating cylinder is equipped with a fry blade and the baffle has an orifice; one end of the filter cartridge is connected to the rotating cylinder and the other end is connected to material conveying pipe.

Working principle of Sawdust dryers/Sawdust dryer for sale/Sawdust rotary dryer

Powdery or granular fly ashes are transferred to feeder by conveyor belt and the feeder transports materials to drying drum; under the turning role of the shovelling plate, materials are uniformly dispersed to be fully contacted with hot air to reach the drying purpose. Dried materials are discharged in the drum terminal through unloader.

1. Guiding area, wet sawdust will rapidly evaporate large amounts of water after entering into this area and contacting with high temperature negative pressure hot air, so wet sawdust will be imported to next work area without forming a bond.

2. Clean-up area, wet sawdust material is in curtain state in this area, so materials are easily to bond when they fall down, the cleaning device in this area will quickly clean out the sawdust bonded cylinder wall and break block sawdust to increase the heat exchange area and improve the drying rate.

3. Inclined lifting plate area, this area is a low-temperature drying area, in which area the sawdust is in a loose state with low moisture to avoid bonded phenomenon, the finished product will enter into the final discharging area after heat exchanging.

4. Discharging area, the finished materials scroll to the discharging port and complete the entire drying process in this area.

Characteristics of Sawdust dryers/Sawdust dryer for sale/Sawdust rotary dryer

Since the granule-like wet sawdust is highly dispersed in the gas stream, the entire surface area will be dried, therefore the sawdust dryer has great drying strength and the object of the dried materials can be achieved within a shorter time. Sawdust dryer is easy to maintain and is capable of handling large quantities of materials, the thermal efficiency can be as high as 60%. Sawdust drying machine has simple structure, which includes the hot stove, the feed inlet, the rotating cylinder, filter cartridges, the material feed pipe, the cooling tube , the spout and a rotating cylinder. Air heater, feeder, air drying tube, a cyclone and the fan are important components.

Among the components of the sawdust dryer, the air drying tube is a very important member. It has the following characteristics.

First, since the material is highly dispersed in the gas stream, the airflow dryer has higher drying strength than the other drying machine.

Second, since the drying intensity of the airflow tube is high, the time for drying the wet materials is greatly reduced, which also effectively reduces the operation cost of the dryer and extends the service life.

Third, the structure of the sawdust dryer is very simple. The floor area is very small. It is easy for the construction and maintenance.

1. Rotary dryer is designed with anti-sticky drum-wall and assembled material-lifting board.

2. This drying equipment is divided into secondary-granulating section, balling section, polishing section and drying section, etc. What worth mentioning is that our dryer features convenient installation and transportation as a result of its flange connection.

3. This large sized drying equipment is primarily composed of vibrating feeder, heating furnace, drying device, and air intake and air outlet device, and more.

The vibrating feeder enables materials to spread uniformly on the mesh belt.

An air-intake fan with large air flow blows away water content of materials, and then the water content will be discharged from the air-outlet.

4. Our dryer has the features of low noise, little pollution and good drying effect.

Main Technical Parameters of Sawdust dryers/Sawdust dryer for sale/Sawdust rotary dryer :

Model | Basic Parameters | Power(kw) | Production Capacity(t/h) | Weight | |||

Inner Diameter | Length(m) | Gradient | Rotate Speed | ||||

| Φ0.6x6 | 0.6 | 6 | 5.0 | 3-8 | 3 | 0.5-2.0 | 2900 |

| Φ0.8x8 | 0.8 | 8 | 5.0 | 3-8 | 4 | 0.8-2.5 | 3500 |

| Φ0.8x10 | 0.8 | 10 | 5.0 | 3-8 | 4 | 1.0-3.5 | 4500 |

| Φ1.0x10 | 1.0 | 10 | 5.0 | 3-8 | 5.5 | 1.5-6 | 5600 |

φ1.2×6 | 1.2 | 6 | 5.0 | 5.8 | 5.5 | 8 | 9380 |

Φ1.2x8 | 1.2 | 8 | 5.0 | 5.8 | 5.5 | 12 | 10200 |

φ1.5×12 | 1.5 | 12 | 5.0 | 4.8 | 15 | 12 | 16450 |

Φ1.5x15 | 1.5 | 15 | 5.0 | 4.8 | 15 | 16 | 18240 |

φ1.8×12 | 1.8 | 12 | 5.0 | 4.5 | 18.5 | 18 | 20000 |

Φ1.8x14 | 1.8 | 14 | 5.0 | 4.5 | 18.5 | 20 | 21000 |

φ2.2×12 | 2.2 | 12 | 5.0 | 4.3 | 22 | 22 | 37100 |

Φ2.2x14 | 2.2 | 14 | 5.0 | 4.3 | 22 | 28 | 38830 |

φ2.4×14 | 2.4 | 14 | 4.0 | 3.78 | 30 | 30-35 | 50700 |

φ2.4×18 | 2.4 | 18 | 4.0 | 3.0 | 37 | 35-40 | 54000 |

Φ2.4x20 | 2.4 | 20 | 4.0 | 3.0 | 37 | 40 | 55700 |

φ2.4×22 | 2.4 | 22 | 3.0 | 3.0 | 45 | 38-42 | 57000 |

φ2.8×20 | 2.8 | 20 | 4.0 | 3.7 | 55 | 45-55 | 71000 |

Φ2.8x24 | 2.8 | 24 | 4.0 | 3.7 | 75 | 50-62 | 75000 |

φ3.0×22 | 3.0 | 22 | 4.0 | 3.2 | 75 | 58-70 | 88000 |

Φ3.0x25 | 3.0 | 25 | 4.0 | 3.2 | 90 | 60-80 | 95000 |

φ3.2×25 | 3.2 | 25 | 4.0 | 3.0 | 110 | 75-90 | 166000 |

φ3.6×25 | 3.6 | 25 | 4.0 | 2.7 | 132 | 95-110 | 188000 |

1. Our service engineer would be ready for service 24 hours per day.

2. After receiving information from customer, our service engineer will call to offer a solution within 15 minutes.

3. The time our service engineers need to arrive at where mechanical accident happens: 2 hours for areas near Shanghai; 48 hours for different provinces in China.

Before Sale

Be a good consultant and assistant of our customer, to ensure our customer's investment will be rewarded with great profit.

1. Select the right model of equipment for customer.

2. To meet our customer's special needs, we can design and develop customized mgxk_cps.

3. Provide training for customer's technician.

4. We will send engineer to observe customer's working field to come up with an optimized solution.

During Sale

Respect every customer and provide them convenience and reliability. We are devoted to help customer gain more.

1. Inspect before accept the mgxk_cps sent by us.

2. Assist our customer to make a construction plan.

After Sale

1. The installation and testing of equipment.

2. Train the workers at present.

| Packaging Detail:Standard export container, or in bulks, bare main machines, motors and small parts are packed in wooden cases. |

| Delivery Detail:20 working days |