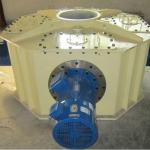

Sawdust charcoal machine

| Type:Sawdust forming machine | Use:Make charcoal briquette | Certification:ISO:9001 | Place of Origin:Henan China (Mainland) |

| Brand Name:De Song | Model Number:M140, M180 | Condition:New | After-sales Service Provided:Engineers available to service machinery overseas |

| Input particle size:<5mm | Moisture of raw material:8%-12% | Raw material:Sawdust straw bagasse rice husk |

Sawdust making machine

Biomass sawdust stick making Machine ,the stick shaping machine is big capacity, low energy consumption, compact and durable. Many performance data such as capacity, coal bar density, eletricity consumption and wearable degree have reached advanced level. It is a newly developed stick shaping machine.

Biomass fuel is made from various biological resources, such as sawdust, wood branch, rich husk, agriculture waste, crop straw, etc. With the reduction of coal resource. Biomass briquette made by machine is with the feature of high density, small volume & good combustibility.

What can be briquetted?

Almost any biomass can be briquetted. Briquetting plants set so far in India are using Saw Dust, Bamboo dust, Bagasse, Cotton Stalk, Coffee husk, Groundnut Shell, Mustard Husk/Stalk, Pine Needles, Rice Husk, Sugar Mill Waste, Jute waste, Coir pith and other wastes & residues like Castor Shell, Red Gram Stalk, Tobacco stem, Tea Waste, Sander Dust, Tree Bark, Wild Grasses & Shrubs and Sander dust etc. can be also be briquetted individually or in combination without using any binder.

How is that going?

Briquetting is a process that biomass is compressed under high pressure and high temperature. The machine uses a large screw to grind, compress and extrude the biomass into briquettes.

During this process, no binder needs to be used. So the output briquette is a type of clean and biomass fuel that is ideal for use in furnaces, boilers and open fires.

Production process of sawdust briquette machine

1. Crushing the raw materials into size no bigger than 5mm.

2. Dry the crushed materials to 8-12%.

3. Pressing to raw material into briquette.

Working principle of sawdust briquette machine

Briquetting is a process that biomass is compressed under high pressure and high temperature. The self bonding of biomass to form a briquette involves the thermo plastic flow of the biomass. The lignin content that occurs naturally in biomass is liberated under high pressure and temperature. Lignin serves as the glue in the briquetting process, thus binding, compressing the biomass to form into high density briquettes.

| Capacity (kg/h) | 140 | 180 |

| Motor power (kw) | 15 | 18.5 |

| electric heating power (kw) | 4.5 | 4.5 |

| product size (diameter x length) | 50x45 | 50x45 |

| Packaging Detail:Container |

| Delivery Detail:15 days |