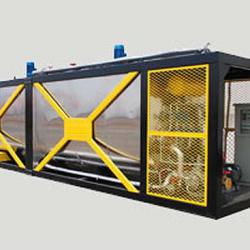

Rubber asphalt production workshop

| Condition:New | Place of Origin:Beijing China (Mainland) | Brand Name:MAYASTAR | Model Number:GYXL3515 |

| Usage:asphalt | Weight:10t | Dimension(L*W*H):10300*2600*3500 |

Rubber asphalt production workshop

Equipment introduction

GYXL3515 rubber asphalt production equipment is the first domestic special equipment that used for producing rubber asphalt.

In our country, rubber powder production technology is mature, and rubber asphalt has passed appraisal in the application of highway construction, its road performance is good, which has the effect of reducing noise, it solves the social and environmental issues that waste tire brings. For highway maintenance, it can save investment. It is one of the effective technologies to solve the road problem of heavy traffic and early damage in our country, it can provide a durable, level off, comfortable, quite environmental quality pavement, and it has a good application prospect.

Rubber powder conveying device:it is consist of screw conveyor, with the advantages of mobile convenience, high efficiency and etc.

Heating system:it is consist of burner, heat conduction oil, heat conduction oil pump and heat exchange device, it can heat very fast to ensure enough quality to the system.

Asphalt pumping device:it is consist of asphalt pumps, piping, and drive device, so it can realize asphalt extraction, suction and cycle in reaction tank.

Mixing device:it adopts unique high speed rotary cutting mixing plant, to premix matrix asphalt and rubber powder uniformly.

Mixture reaction device:it is composed of a tank body and a stirring device to make the matrix asphalt and rubber powder mixture for uniform swelling reaction, and the tank uses a unique thermal insulation technology to ensure the temperature of asphalt in the swelling reaction.

Major advantage

1,Rubber powder and asphalt ratio can be setted at any time according to user requirements.

2,The maximum productivity of each cycle of production can be setted arbitrary.

3,Weighing system measuring accuracy, weighing precision is less than 2%.

4,Fast heating and good performance of heat preservation are advantageous in the process reaction of rubber powder modified asphalt.

5,High efficiency mixing is beneficial to the process of rubber powder modified asphalt mixing and storage.

6,The tank with powerful homogenizing device can avoid the medium segregation, precipitation, homogeneous swelling reaction.

7,Using the heat conduction oil safety rapid heating system, high heating efficiency, short preheating standby time, reduce production auxiliary time.

8,Good thermal insulation layer can ensure static heat preservation performance index acuities 12°C/8 hours

9,The outer packing is made of stainless steel, nice, anti-corrosion and durable.

10,The overall design of frame structure, so it can easy to move and rapid assembly.

Main parameters:

model: GYXL3515

production quantity: 12-18t/h

tank volume: 35000L

asphalt heating method:diesel burner

rubber powder fineness: ≥20(mesh)

rubber powder content: ≤25(%)

total weight: 10000kg)

contour dimension: L×W×H=10300×2600×3500(mm)

| Packaging Detail:nude |

| Delivery Detail:30 days |