Rotary kiln hot sale in South Africa for Active Lime

| Condition:New | Place of Origin:Henan China (Mainland) | Brand Name:Hongji | Model Number:2.5x45m |

| Voltage:220//380/440V | Power(W):55 | Weight:167.5T | Certification:ISO9001:2008, SGS, BV, IQNET |

| Warranty:All using life | After-sales Service Provided:Engineers available to service machinery overseas | Kiln type:Horizontal | Fuel:Oil, gas, coal and so on |

| Shall material:Mild steel | Shell thickness:30mm | Motor:YCT355-4A/ 55kw | Gearbox:ZS145-11 I=157 |

| Fire bricks:Al2O3 â¥70%. thickness 200mm | Bricks heat resist:under 1300â | Capacity:200tpd | Kiln thermal efficiency:50-65% |

Hongji Rotary kilnis a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. Materials produced using rotary kilns include:

- Cement

- Lime

- Refractories

- Metakaolin

- Titanium dioxide

- Alumina

- Vermiculite

- Iron ore pellets

Rotary kiln structure

The basic components of a rotary kiln are theshell,the refractory lining,support tyres and rollers,drive gearandinternal heat exchangers.

The kiln connects with a material exit hood at the lower end and to ducts for waste gases. This requires gas-tight seals at either end of the kiln. The exhaust gas may go to waste, or may enter a preheater which further exchanges heat with the entering feed. The gases must be drawn through the kiln, and the preheater if fitted, by a fan situated at the exhaust end. In preheater installations which may have a high pressure-drop, a lot of fan power may be needed, and the fan is often then largest drive in the kiln system. Exhaust gases contain dust and there may be undesirable constituents such as sulfur dioxide or hydrogen chloride. Equipment is installed to scrub these out before the exhaust gases pass to atmosphere.

Rotary kiln workin principle

The kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis. The material to be processed is fed into the upper end of the cylinder. As the kiln rotates, material gradually moves down towards the lower end, and may undergo a certain amount of stirring and mixing. Hot gases pass along the kiln, sometimes in the same direction as the process material (co-current), but usually in the opposite direction (counter-current). The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. Such a flame is projected from a burner-pipe (or "firing pipe") which acts like a large bunsen burner. The fuel for this may be gas, oil or pulverized coal.

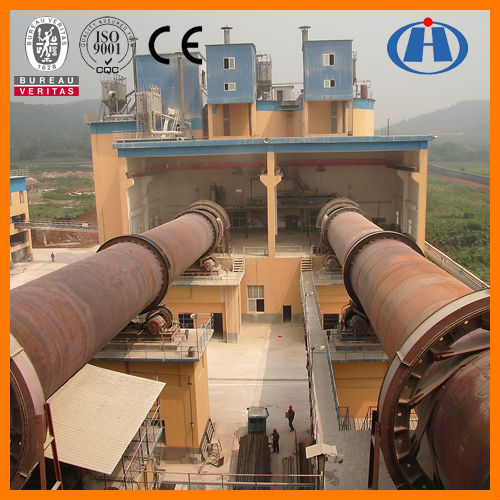

Rotary Kiln in work shop

Rotary kiln delivery

Rotary kiln working in factory

Place order or send inquiry, we would like to hear from you with the following information:

-What kind of material you are going to calcine with the kiln?

-Material size feed to the kiln please?

-What is the capacity you need per day?

-What kind of fuel available in local?

-Plant sea level?

Henan Hongji could supply you best proposal, do not hesitated contact us now !

Contact information:

Add: No.668 West Zhongyuan Rd,Zhengzhou·China

Contact person: Kelly Liu

TEL: 86-371-67662768

M.P.: 86-15137190419

Skype: kellyliu_1987

| Packaging Detail:Nude packing load in container or bulk freight, small parts with wooden case load in container |

| Delivery Detail:20-60 days after confired the order |