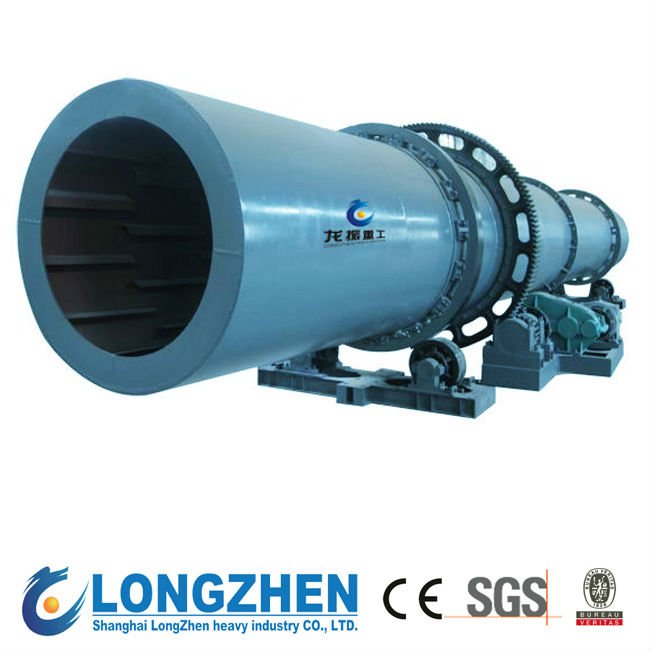

Rotary Dryer For Iron Ore

| Place of Origin:Shanghai China (Mainland) | Brand Name:Lonzhen | Model Number:drum series | Condition:New |

| After-sales Service Provided:Engineers available to service machinery overseas | Model:rotary dryer | Color:Green | Certificate:CE/SGS/BV |

| CQC:ISO | Price:Negotiable | Application:Ore,rock and so on |

Rotary Dryer For Iron Ore

Rotary Dryer Advantages

1.The rotary dryer has rational design of spreading materials plate distribution and angle, which has reliable performance, so it has the characters of high thermal utilization ratio, dry and even, litte times of cleaning materials, convenient maintenance and the like;

2.The equipment adopts self-aligning type of tug structure, the tug cooperates well with rolling ring,which decreases greatly the abrasion and power consumption;

3.Specially designed block wheel structure of this machine decreases greatly the horizonal thrust that is produced by working obliquely.Resistance to overload ability is strong, cylinder runs stably, it has high reliability;

4.Rotary dryer has the character of thermostability,it can dry materials by using high temperature and hot air.It has strong extensive ability,when designing it takes production allowance into consideration,even productivity is increased by little extent,it is unnecessary to renew equipment;

5.Cylinder dryer has big handling ability, investment is little and drying cost is low;

Rotary Dryer Introduction

The rotary dryer made by out company is mainly used in building materials,metallurgy,chemical plant,cement plant for drying of limestone slag,coal powder,slag,claystone.This dryer is formed by rotary body,lifting blade,driving deviece,supporting device and sealing ring.The dryer has advantages of reasonable structure,high efficiency,low energy consumption and being convenient for transportion.

Rotary Dryer Working Principle

Rotary dryer consists of gyrorotor,spreading materials plate,transmission device, back-up unit, seal ring and the like.Dried materials are sent hopper by belt conveyor or bucket elevator,then pass through feeding machine of hopper and charging pipe into feeding end.Inclination of charging pipe is bigger than materials’ angle of crater,so that materials can flow into dryer smoothly.Cylinder of drier is rotating cylinder which forms slight slope with horizonal level. Materials are added from relatively higher end,heat-carrying agent enters from low end,it has counter-current contact with materials,heat-carrying agent and materials form cocurrent flow and enter into cylinder.

Rotary Dryer Technical Specifications

| rotary dryer | Transfers barrel dryer(mm) | Transfers barrel length(m) | Gradient (.) | Rotational speed` (r/min) | Weight (t) | Power (kw) | Volume/cube (t) |

| HG0.6*8 | 600 | 8 | 3-5 | 8 | 5.1 | 4 | 2.26 |

| HG0.8*10 | 800 | 10 | 3-5 | 7.2 | 6.9 | 4 | 5.02 |

| HG1.0*10 | 1000 | 10 | 3-5 | 6.73 | 7.5 | 5.5 | 7.85 |

| HG1.2*12 | 1200 | 12 | 3-5 | 5.8 | 13.1 | 11 | 13.31 |

| HG1.5*12 | 1500 | 12 | 3-5 | 4.8 | 22.3 | 15 | 21.2 |

| HG1.8*14 | 1800 | 14 | 3-5 | 3.2 | 45.8 | 30 | 48.22 |

| HG2.2*18 | 2200 | 18 | 3-5 | 3 | 50.3 | 37 | 70.43 |

| HG2.4*20 | 2400 | 20 | 3-5 | 2.83 | 78.4 | 45 | 90.43 |

| HG2.8*24 | 2800 | 24 | 3-5 | 2.59 | 97 | 75 | 147.8 |

| HG3.0*20 | 3000 | 20 | 3-5 | 2.6 | 102 | 55 | 141.3 |

| HG3.0*25 | 3200 | 25 | 3-5 | 2.6 | 110 | 75 | 176.7 |

| Packaging Detail:Standard export containers |

| Delivery Detail:45 days after deposit |