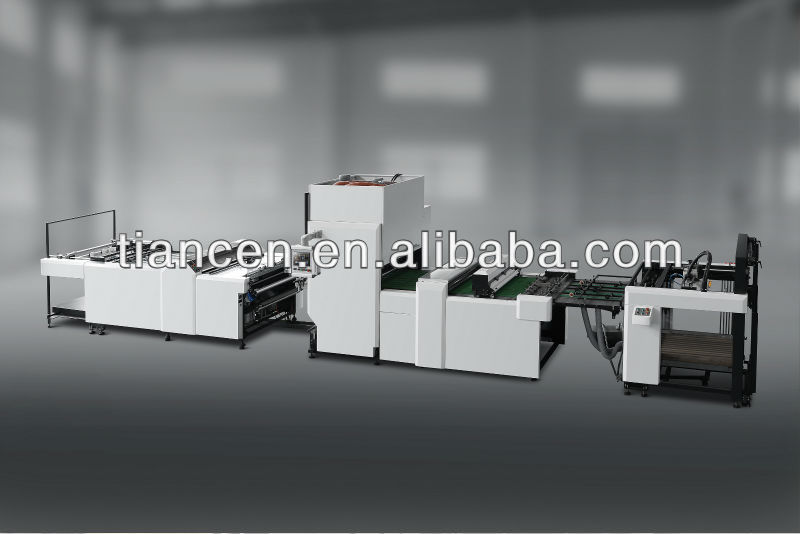

RFM-105 Automatic PET Film Laminator

| Condition:New | Type:Laminating Machine | Automatic Grade:Automatic | Place of Origin:Shanghai China (Mainland) |

| Brand Name:Tiancen | Model Number:RFM-105 | keyword:film laminating machine |

RFM-105 Automatic PET Heating Knife Laminating Machine

Film laminating machine

1.Professional manufacturer

2.PET heating knife laminating machine

3.Good quality made in shanghai

RFM-105 Automatic PET Heating Knife Laminating Machine

Advantages of the machine

Heating knife laminating machine is invented by Tiancen company firstly in China. It is suitable for PET film,Metal film,OPP film and some other films.

High degree of automation, multi-purpose, energy-saving and high configuration, mainly using imported electrical installations.

The whole machine is controlled by OMRON and PLC. The speed for each section matching with main section is controlled by OMRON inverter. So it can be automatically increased or decreased. Advanced big size colorful touch screen is easy and convenient to control.

This machine is composed of automatic feeder, cleaner, gluing section, drying chamber, laminating section, separating section and automatic delivery. It also can work with water-based, oil-based glue and pre-coated film.

CONFIGURATION AND MAIN FUNCTIONS:

1.High-speed sheet feeder:

Automatic pre-stack feeding with Pre-stack feeding table and non-stop device, high precision on paper feeding, the front and rear overlap errors and left and right errors are not larger than 2mm due to adopts servo technology.

2. Electric heating/brush cleaning:

Wheel brush and electric heating powder removing devices, with an environment-friendly filter, The reversal wheel brush design ensures the powder removing, in order to prevent paper from being deviated, the machine adopts an intensive powerful air suction platform.

3.Gluing and pressing principal machine (with thin paper rolling):

Drying chamber has energy-saving devices. To compare with traditional laminating, this new model laminating machine can save energy 30%. The machine ceramic roller is used to gluing, hot roller and pressure roller adopts hot-water constant temperature, Pressure roller and pressure film roller are both automatically controlled, air suction is performed in the whole sheet transfer process, the tension of the film is automatically controlled.

4. Finished products separating(Heating knife):

The machine adopts heating knife to separate OPP,PET,PVC films and so on. It will not damage the surface of sheets. The separating position is accurate and reliable. The pressure roller which is similar like scissors separates sheets rapidly.

5.Automatic delivery: (with auxiliary paper delivery board)

It is working through three pneumatic bats from different sides, collect the papers neatly, pressure wave structure matching product rapidly.

Technical Variables

| Max paper size | 1040×1040 mm |

| Min paper size | 350×350 mm |

| Paper weight | 128~450 g/m2 |

| Max laminating width | 1040 mm |

| Film diameter | 600 mm |

| Core diameter | 3″ |

| Type of adhesive | opp/pet/water-based/solvent-based glue and (optional pre-coated film) |

| Speed | 10~60 M/min |

| Height of feeding pile | 1060 mm |

| Height of stacker pile | 1100 mm |

| Max pile weight | 1000 kg |

| Electricity | 72 KVA |

| Electric consumption | 64.6 KVA |

| Overall dimension (L×W×H) | 14.1×2.8×2.57 M |

| Machine weight | 7200 kg |

| Packaging Detail:Wooden case |

| Delivery Detail:60 days |