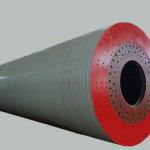

Reliable quality ball mill for ceramic industry from China supplier

| Condition:New | Type:Ball Mill,ball mill for ceramic industry | Motor Type:AC Motor | Power(W):7.5-300 KW |

| Capacity(t/h):0.2-10 | Place of Origin:Henan China (Mainland) | Brand Name:Lanji | Model Number:TCQ1500*1800 |

| Dimension(L*W*H):10*2.5*2.8 M | Weight:3-80 T | Certification:ISO9001 | Warranty:1 Year |

| After-sales Service Provided:Engineers available to service machinery overseas | Application:mixing, grinding of feldspar, quartz, clay | Rotary speed:14-36 r/m | Power:5.5-90Kw |

Reliable quality ball mill for ceramic industry from China supplier

Intermittent ball mill:

This machine works in both dry and wet methods intermittently, to mill, mix and discharge materials such as feldspar,quartz and clay. The slurry can pass through 1000 sieve pore. It's a kind of super fine grinding mill, so the feed materialhould be in medium size to get best grinding efficiency and economic profit.

Intermittent ball mill working Principle:

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to thegrinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications ofsteel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height andimpact and grind the materials. The ground materials are discharged through the discharging board thus the grinding processis finished.

Intermittent ball mill Structure:

The machine is composed by feeding part, discharging part, turning part and driving part (reducer, small driving gear,electric motor and electric control). The quill shaft adopts cast steel part and the liner is detachable. The turninggearwheel adopts casting hobbing process and the drum is equipped with wear-resistant liner, which has good wear-resistance.The machine is with stable and reliable working condition.

Intermittent ball mill Technical data :

| Model | Capacity(t/h) | rotation speed(r/min) | Power(kw) | Weight(t) |

| TCQ910×1120 | 0.2 | 36 | 5.5-11 | 3 |

| TCQ1200×1400 | 0.5 | 32 | 11-18.5 | 3.8 |

| TCQ1500×1800 | 1 | 28 | 15-22 | 4.5 |

| TCQ1800×2100 | 1.5 | 26 | 18.5-30 | 6 |

| TCQ2100×2100 | 2.5 | 22 | 22-37 | 7.4 |

| TCQ2200×2400 | 3 | 20 | 28-45 | 8.2 |

| TCQ2500×2900 | 5 | 16 | 37-55 | 9.3 |

| TCQ2800×3700 | 8 | 14.5 | 55-75 | 12.5 |

| TCQ3000×3700 | 10 | 14 | 75-90 | 18.6 |

| Packaging Detail:standard export package |

| Delivery Detail:10-15 days after down payment |