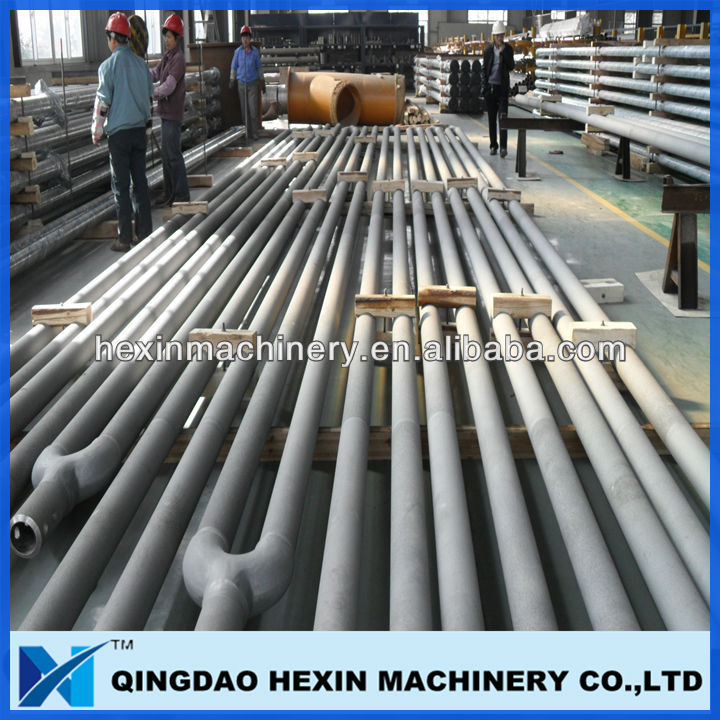

reformer/catalyst tubes for Petrochemical Industry

| Place of Origin:Shandong China (Mainland) | Brand Name:Hexin | Model Number:reformer tube TR-0818003 | Application:Petrochemical Industry |

| Certificate:SGS |

reformer/catalyst tubes for Petrochemical Industry

Tubes assemblies for steam reformer and steam reformer, reformer/catalyst tubes, radiant coils, reformer harp coils, cracker tubes, ethylene cracking (pyrolysis) coils, hairpins, hangers, outlet collectors, inlet and outlet manifolds, tube stanchions, convection coils, pigtails, tube sheets, tube supports, transfer lines, furnace hooks, T-pieces ,Y-pieces, flanges, pump, valve and other static castings

| Name | Reformer Tube |

| Application | Steam reformer and cracker, ammonia production, convection furnaces, direct reduction of iron (DRI), ethylene pyrolysis, hydrogen production, methanol production |

| Process | centrifugal casting, static casting, hole boring, welding |

| Material | High nickel and high chrome heat resistant alloys, cobalt base alloys, like HU, HT, HK, HP, HW, 24/24NbTiZr, 50Cr/50Ni (2.4813), 1.4865, 1.4849, 1.4848, 1.4410, 1.4059, 1.4841, 1.4845, 1.4852, 2.4879 or as per customer's requirements |

| Other relative products | Reformer Tube, Catalyst Pipe, Heat-resistant Alloy Centrifugal Spun Casting, Stainless Steel Pipe |

| Standard | ANSI, ASTM, ASME, DIN, GB |

| Certificates | 3.1B material certificates, SGS certificate |

| Quality control | We have in-house facility for each inspection: Chemical analysis by spectrometer Measurement inspection Mechanical properties testing, pressure testing, non destructive inspection (NDT): ultrasonic, X-ray, PT, eddy current testing |

High quality welding

Strict testing

Only use austenitic stainless steel ball in shot blasting to guarantee the wonderful surface

Uniform cast skin

Bore surfaces finished to be Ra= 3.2 μm or better

Comprehensive testing for every tube

We carry out very strict quality control from raw material to each step of the process, until the finished product is dispatched. To make sure the highest quality possible, each test is carried out strictly with our in-house testing facilities.

Advantages:

(1). Concentrate in Petrochemical Industry more than 30 years

(2). Complete engineering and manufacturing services, tooling and gauging design, integrated CAD/CAM system, test and measuring including CMM

(3). Experienced workers for forging, machining and welding guarantee excellent quality and prompt delivery

(4). Focused sales and customer-service team

In one word, we do everything we can to make your job easier.

| Packaging Detail:sea worthy packaging, wooden, steel cases packaging or as per customers' requirements |

| Delivery Detail:1-6 months according the quantity |