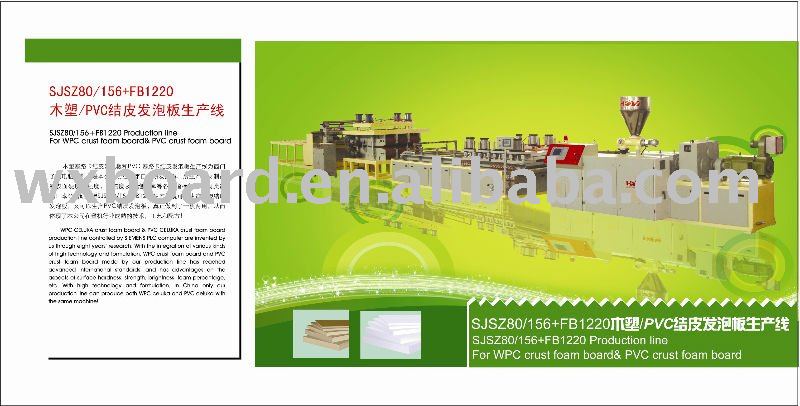

PVC foam board extrusion line

| Place of Origin:Jiangsu China (Mainland) | Brand Name:HONGYI | Model Number:T=8~25mm, WxL=1220x2440mm | Printing, hot stamping or painting:wood color or as you wish |

A. Summary about PVC skinning foaming board production line:

A1. Working condition: 380V/3Phases/50HZ, Siemens computer controlling system with two touch color screens.

A2. Material: PVC powder, CaCo3 powder, chemical additives.

A3. Product specification: T=8~25mm, WxL=1220x2440mm, Density>0.55g/m3, Surface hardnes(Shores): 55~75, which will hard enough to opposite finger nail mark and screws holding capacity will be strong enough as you want to have.

A4. Consumption: Installed power=200kw, working power=140kw, water=25.0m3/h, air=50L/h.

A5. Max extrusion output: 360kg/h, which means 8MT/day.

A6. Dimension: 25,000X2,500X2,500mm.

A7. Application:

PVC skinning foaming boards are mainly used as high-end and environment-friendly products, such as high-class furniture, high-class bathroom cabinet and advertisement board, and they are well-known adopted in star-level hotel and luxury sites, which medium density fiber panel can not be compared with.

According to the development trend of new economy in 21th century, they are starting to become more and more popular not only in China, but also in other developed countries, like Europe, America, Japan, Russia and other countries.

A8. Characteristics and performance:

The whole line is controlled by computer system. It is easy to control, high output, running steady and reliable. PVC skinning foaming board made by this machine have the characteristics of sound separation, heat-proof, temperature keeping, moisture proof and mildew proof etc. The luster of products could remain forever and not easy to aging. The surface of products has strong hardness. They are environment friendly, recyclable for almost 100%, incombustible and safe for using. Drilling, sawing, nail, planning, bonding can be conducted like timber material. The normal tools for wooden material can be worked. The surface of this product is smooth and can be painted, printed and hot stamped as you wish.

B. Summary about W=1220mm PVC skinning foaming boards:

B1. Product specification: T=8~25mm, WxL=1220x2440mm, Density>0.55g/m3, Surface hardnes(Shores): 55~75, which will hard enough to opposite finger nail mark and screws holding capacity will be strong enough as you want to have.

B2. Output: 300kg/h normally, so we get following datas:

B2.1. 1.22*2.44*8mm Density:0.55g/cm3 Weight: 13.09kg/sheet output:23 sheets/h

B2.2. 1.22*2.44*10mm Density:0.55g/cm3 Weight: 16.36kg/sheet output:18 sheets/h

B2.3. 1.22*2.44*12mm Density:0.55g/cm3 Weight: 19.64kg/sheet output:15 sheets/h

B2.4. 1.22*2.44*14mm Density:0.55g/cm3 Weight: 22.91kg/sheet output:13 sheets/h

B2.5. 1.22*2.44*16mm Density:0.55g/cm3 Weight: 26.18kg/sheet output:12 sheets/h

B2.6. 1.22*2.44*20mm Density:0.55g/cm3 Weight: 32.76kg/sheet output:9 sheets/h

Every year there are many buyers from India(Sintex industries ltd, a strong national company in India), Brazil and Eastern Europe come to our companys to visit production process and we have exported not only to these countries but also other nations and regions like Vietnam, Malaysia, Bengal and Taiwan.

We have a special factory for testing and producing PVC/WPVC free foaming sheets and celuka/skinning foaming boards. You and your clients will see the whole and detailed producing process when you come to visit our two companys in Wuxi City, Jiangsu Province, 3 hours from Shanghai airport where we pick you up. And it is also our biggest and strongest shining point in this area that no one could compare with us nowadays in Southeast China.

Best Regards!

| Packaging Detail:Standard wooden case or packed as you wish |

| Delivery Detail:Normally within 60days in receipt of deposit |