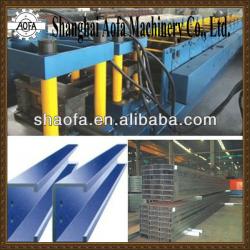

purline making cold roll forming machine

| Type:Steel Frame & Purlin Machine | Condition:New | Work Pressure:230mpa | Production Capacity:8-10m/min |

| Place of Origin:Shanghai China (Mainland) | Brand Name:Aofa | Model Number:AF-C80-300 | Voltage:380V |

| Power(W):7.5KW | Dimension(L*W*H):8m*1.3m*1.4m | Weight:5T | Certification:SGS |

| Warranty:18month | After-sales Service Provided:Engineers available to service machinery overseas | Name:purline making cold roll forming machine | Machine color:as require |

| Conrol system:PLC | Cutting type:hydraulic | Driven type:chain | Size of container:40GP |

| Usage:building | Life long:10year |

purlin making cold roll forming machine

Other machine we manufacture

Cold roll forming mahcine, color steel roll forming machine,roof and wall panel machine,decking floor roll forming machine,floor decing forming mahcine, stud and track roll forming machine,highway guardrail roll forming machine,cable tray machine, and so on.

Profile drawing:

Working flow:

Decoiler-----feeding----- leveling ------roll forming ------punching------cutting----output table

Machine components:

Roll forming main machine------------------1unit

Manual Uncoiler-------------------------------1unit

Cutting device----------------------------------1unit

Punching device-------------------------------1unit

Control system---------------------------------1unit

Hydraulic station-------------------------------1unit

Output table-------------------------------------1unit

Main technical parameter:

1. DECOILER:

(1)Max. Width: 500 mm

(2)Inner Diameter: Φ350 – Φ500 mm

(3)Out Diameter: 1500 mm

(4)Max. Loading Capacity: 5000 kgs

2.LEVELING DEVICE:

(1)Max. Width: 600 mm

(2)Thickness: 1-3 mm

(3)Rollers for Leveling: 5 rollers

(4)Material for Rollers: GCr15 steel

(5)Hardness for Heat Treatment: HRC55 – 60°C

3. HYDRAULIC PUNCH DEVICE:

(1)Adopted with 4 pillars hydraulic punches.

(2)Length for Punch Table: 1.2m*1.5 m

(3)Motor for Hydraulic Punch: 7.5 kw

(4)Hole-Punching Modular: 3 Pics

4.ROLL FORMING MACHINE:

(1)Rolled Material: Cold Rolled Steel Sheet

(2)Material Thickness: 1-3 mm

(3)Rollers: 15Groups

(4)Material for Rollers: GCr15 steel

(5)Material for shaft:GCr15 steel

(6) Hardness for Heat Treatment: HRC55 – 60°C

(7)Diameter of shaft: 80mm

(8)Frame panel thickness: 20mm

(9)Bottom frame:36# H-section steel

(10)Motor Power: 15 kw

(11)Speed Reducer Model: QZ 400

(12)Rolling Speed: 2 – 8 m / min; Adjustable

(13)Driven type: 2"Chain

5.CUT-OFF DEVICE:

(1)Material for Cut-Off Modular:Cr12 steel

(2)Hardness for Heat Treatment:HRC55 – 60°C

(3)Cut-Off Type:Hydraulic, Automatic Cut-Off

(4)Cut-Off Modular:1 set

(5)Motor for Hydraulic Stand: 5.5 kw

6.ELECTRONIC CONTROL SYSTEM:

(1) Type: PLC Frequency Control System with touch screen

(2) PLC Brand:Japan Panasonic

(3) Encoder Brand: Omron

(4)Length Error:±2mm

7.Output table

It is simple and used to load finished product.

Length:6m

Terms

| Payment type | 30% T/T prepaid and balance should be paid before loading |

| Delivery time | 30 working days after receiving prepaid |

| Guarantee period | 18monthes free service/ pay service all the machine life |

| Installation and training | If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face. video to teach you to install and operate. please arrange board and lodging and other necessary things |

Machine pictures:

We can produce machine as different profile drawing.

Contact person: Abby Song

Mobile number: 0086-18701854523

Skype: abbasong249

| Packaging Detail:Standard (40GP) |

| Delivery Detail:30 working days after receiving prepaid |