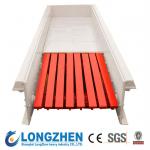

Professional vibrating feeder suppliers/Direct supply vibrating feeder equipment

| Condition:New | Application:ore, rock, stoe, etc.,Ore | Power Type:Electric | Capacity(t/h):200-400 |

| Place of Origin:Henan China (Mainland) | Brand Name:Kefan | Model Number:GZD-500*120 | Power(W):5.5*2 |

| Dimension(L*W*H):5450*2000*1300 | Weight:5.2 | Certification:BV/CE/ISO | Warranty:2 years |

| After-sales Service Provided:No overseas service provided | price:competitive | color:as you like | material:wear-resistant |

| testing:professional | market:globle | maintenance:convenient | after-sale service:whole life |

| Hopper Size(mm):5000*1200 | Max.Feed Size(mm):600 | installation:under engineer guide |

Application ofvibrating feeder

Vibrating feeder can feed block or granule materials from the material storage to charging device evenly and continuously. It can realize even feeding for crushers in sandstone production line and achieve rough screening for materials.Vibrating feeder is widely applied in combined operation of crushing and screening in the industries like metallurgy, mine, mine ion, building materials, chemicals, etc.

In the Sand-Stone production line, it can send materials to crusher evenly and continuously and at the same time, it can screen materials roughly.It can be used in these areas such as metallurgical industry, coal mining industry, mining-selecting, building, chemical and grinding industry etc.

Working principle of vibrating feeder

Vibrating feeder consists of vibrating frame, spring, vibrator, motor vibrating device and motor. The vibrator is made of two fixed eccentric shafts whose gears are jogged.In installation, the two gears must be jogged according to the sign. Through drive of the motor, the two eccentric shafts start rotating to produce a linear huge power which forces the feeder to vibrate.Through vibration, the materials will slip and sling on the funnel, moving forward; when the materials pass the screening part, smaller parts will fall down, avoiding the further crushing, so screening purpose can be reached.

Advantages of vibrating feeder

Smooth vibration, reliable operation, long service life, low noise, low power consumption, easy to adjust, simple structure, easy to install, light weight, small volume, simple maintenance

Flow chart for ore processing

For sand making production line

Technical parameters of vibrating feeder

| Model | Hopper Size(mm) | Max.Feed Size(mm) | Capacity(t/h) | Eccentric Shaft Rotate Size(r/min) | Motor Power(KW) | Weight(t) | Overall Dimensions(mm) |

| GZD-250*75 | 2500*750 | 300 | 50-80 | 1.5*2 | 1.29 | 2580*1430*600 | |

| GZD-300*90 | 3000*900 | 450 | 80-100 | 3.0*2 | 2.96 | 3064*1580*1414 | |

| GZD-370*100 | 3700*1050 | 500 | 100-150 | 3.7*2 | 3.7 | 3980*1878*866 | |

| GZD-490*110 | 4900*1100 | 580 | 120-280 | 5.5*2 | 4 | 5200*1900*1200 | |

| GZD-500*120 | 5000*1200 | 600 | 200-400 | 5.5*2 | 5.2 | 5450*2000*1300 | |

| ZSW-350*96 | 3800*960 | 500 | 100-160 | 500-720 | 11 | 4.21 | 3882*1684*1340 |

| ZSW-490*110 | 4900*1100 | 580 | 120-280 | 500-800 | 18.5 | 5.41 | 4957*1841*1365 |

| ZSW-590*110 | 5900*1100 | 600 | 200-350 | 500-800 | 22 | 6.05 | 6000*1841*1365 |

| ZSW-600*130 | 6000*1300 | 600 | 400-560 | 500-800 | 22 | 7.5 | 6082*2040*1580 |

| ZSW-600*150 | 6000*1500 | 800 | 400-700 | 500-800 | 37 | 8.5 | 5955*2210*1510 |

Services

Our highly skilled technicians and experienced after-sale series team will provide you the most professional serive.

1)Help customers to choose the most appropriate equipment model.

2)Design and make productions based on customer's special requirement.

3)Products will be strictly inspected before loading.

4)Shipping delively will be based on the contract.

5)We are also offering plenty of accessories and various spare parts.

Our products have CE,ISO9001:2008 certificated,so you can feel relieved for our product.

If you need more informations,pls feel free to contact me at any time!!!

If you have any question,please don't hesitate to tell us!

| Packaging Detail:standard package |

| Delivery Detail:15-30 days timely |