professional supplier provide gypsum board manufacture equipment

Gypsum board production line, 1. CE/ISO 9001:2000 certification, 2. full automatic, 3. large capacity - details see: https://www.machineto.com/professional-supplier-provide-gypsum-board-manufacture-equipment-10087645

| Brand Name:TC | Model Number:TC052 |

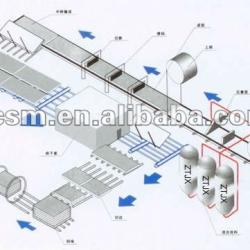

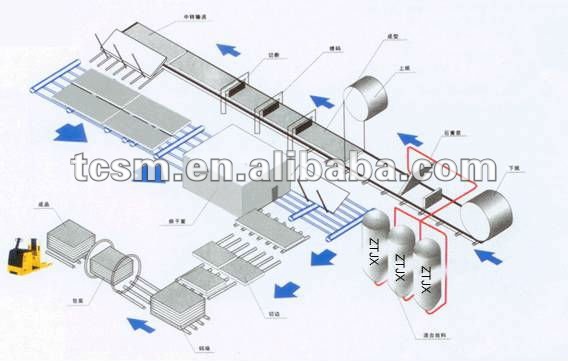

Paper Faced Gypsum Board Production Line

1.Capacity:2 million m2/y~50 million m2/y (thickness of 9.5mm)

2.AutomationFully automatic

3.Drying systemUsing hot air for drying

4.Fuel: Coal, natural gas, heavy oil and diesel oil

5. Main materials:

Construction gypsum powder, modified starch, protective paper, foaming agent, water, white latex. Fiberglass and paper pulp (adding selectively according to different raw materials and kinds of products)

6.Quantity of raw material requiredfor producing per m2 gypsum board (referenced data) (thickness of gypsum board: 9.5mm)

| Gypsum powder(CaSO4·1/2H2O) | 6.8kg/m2 |

| Protective paper | 0.48kg/m2 |

| Modified starch | 0.035kg/m2 |

| Foaming agent | 0.008kg/m2 |

| White latex | 0.005kg/m2 |

| Fiberglass (used selectively ) | 0.025kg/m2 |

| Electricity | 0.3kwh/m2 |

| Water | 4.8kg/m2 |

| Heavy oil | Heat consumption~3800kcal/m2 |

| Natural gas | Heat consumption~3800kcal/m2 |

| Packaging Detail:container.ship or railway .It will need about 4-20 contaienrs,which depends on production capacity. |

| Delivery Detail:60 days after the deposit |