Production vacuum freeze dryer/vacuum freeze dryer/pharmaceutical freeze dryer

| Condition:New | Type:Freeze Drying Equipment | Place of Origin:China (Mainland) | Brand Name:LYOMAC |

| Model Number:lyopro-10,13,16,20 | Voltage:380/440V, 60Hz | Power(W):63KW,81KW, 95KW,114KW | Dimension(L*W*H):7000*2000*4200 |

| Weight:12000KG,13000KG,15000KG,18000KG | Certification:CE,GB150 | Warranty:12 months after installed | After-sales Service Provided:Overseas service center available |

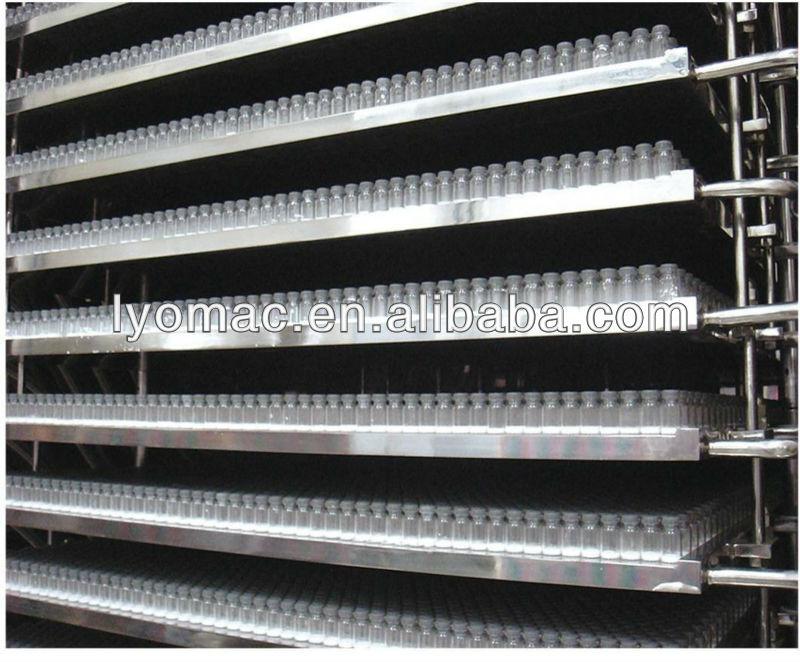

| Drying producct:vial, tray | Shelf temperature:regulatable, range : 80℃~-55℃ | Chamber vacuum:regulatable, ultimate vacuum : 1 Pa(equal to 7.5 mtorr) | Shelf space:Customerized design, regulatable design |

| Utilities:Power, compressed air, Optional for steam and clean water | SCASA system:available as option | PLC system:Optional as Siemens or Omron | Chamber Isolation valve:Butterfly valve and mushroom valve |

| CIP system:available as option | Regulation:cGMP, FDA, CE , GB150 |

Production vacuum freeze dryer/vacuum freeze dryer/pharmaceutical freeze dryer

Technical Data

Utility Requirement

· 380V, 50Hz/440V,60Hz, 3-phase, 5 wires

· Cooling water for compressor(1.5≤P≤2bar, T≤25°C)

· Steam for sterilizing or defrosting(2≤P≤3bar)

· WFI for cleaning(P≥4bar, T=80°C)

· Compressed air for pneumatic system(5≤P≤8bar)

· Inert gas for vacuum release(0.5≤P≤1bar)

Performance Specifications

· Shelf temperature range: -55°Cto +80°C

· Shelf cooling rate: 20°Cto - 40°C≤ 60 min

· Shelf heating rate: Approx. 1°C/min

· Condenser final temperature: ≤ -75°C

· Condenser cooling rate: 20°Cto - 40°C≤ 30 min

· Final vacuum: ≤0.01 mbar

· Evacuation rate: 1000mbar to 0.1 mbar ≤ 30 min

· Leakage rate: ≤0.03mbar•L/sec

Chamber/Door

Chamber

1.GB-150/PED/ASME Code Pressure Vessel.

2.cGMP guidelines and US-FDA recommendation.

3.Leak tested with helium leak detector.

4.X-ray weld tests.

5.Piping connections with sanitary clamps.

6.Sanitary clamp capped validation port on chamber.

7.All edges and corners are rounded to facilitate cleaning.

8.Dead-legs are limited to a length to diameter ratio L(length) / d(diameter) ≤3, and are sloped to ensure free draining. Where the length to diameter ratio can not beachieved, cleaning action is provided with spray-nozzle.

9.Chamber bottom is sloped to drain.

10.Cooling jackets for rapid cool down after sterilization with steam.

| Type | Rectangular |

| Maximum design pressure | 3barA |

| Maximum design temperature | 134°C |

| Sloping | 2% |

| Finish | Ra≤0.4µm |

| Material of product contact | AISI-316 L |

Door

1.Door sealing is a solid single gasket designed for high vacuum and overpressure operation.

2.Automatic locking mechanism is interlocked and controlled by PLC and its moving parts are in the machine room for easy maintenance.

3.Interlocking mechanism: the door can not be opened in case the pressure in the chamber is higher than atmospheric pressure.

| Finish | Ra≤0.4µm |

| Gasket | Silicone rubber single gasket |

| Locking arrangement | Automatic |

| Material of product contact | AISI-316L |

For more information,please contact us…

Technical Specifications

LYO- | 0.2 | 0.5 | 1 | 2 | 3 | 5 | 7.5 | 10 | 13 | 15 | 20 | 25 | 30 | 40 | 50 | ||

Usable Shelf Area | m2 | 0.27 | 0.54 | 1.08 | 2.16 | 3.24 | 5.40 | 7.56 | 9.72 | 12.96 | 14.40 | 19.73 | 24.59 | 29.60 | 41.86 | 49.34 | |

Ice Capacity | kg | 4 | 10 | 20 | 40 | 60 | 100 | 150 | 200 | 250 | 300 | 400 | 500 | 600 | 800 | 1000 | |

VialsCapacity (Φ22mm:~10ml) | vials | 550 | 1100 | 2300 | 4600 | 6900 | 11200 | 15700 | 20200 | 27000 | 30000 | 41300 | 51600 | 63300 | 87600 | 100800 | |

Vials Capacity (Φ16mm:~5ml) | vials | 1000 | 2100 | 4300 | 8600 | 13000 | 22000 | 30800 | 39600 | 52900 | 58800 | 80900 | 101100 | 114900 | 171600 | 200000 | |

Shelf | mm | 450 | 450 | 600 | 900 | 900 | 1200 | 1200 | 1200 | 1200 | 1200 | 1495 | 1495 | 1800 | 2000 | 2200 | |

Shelf | mm | 300 | 300 | 450 | 600 | 600 | 900 | 900 | 900 | 1200 | 1200 | 1200 | 1495 | 1495 | 1495 | 1495 | |

Number of | loaf | 2+1 | 4+1 | 4+1 | 4+1 | 6+1 | 5+1 | 7+1 | 9+1 | 9+1 | 10+1 | 11+1 | 11+1 | 11+1 | 14+1 | 15+1 | |

Shelf Spacing | mm | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 90 | 100 | 100 | 100 | 90 | 90 | |

Power Supply | kw | 4.5 | 6 | 14 | 21 | 29 | 43 | 54 | 66 | 85 | 85 | 117 | 133 | 152 | 184 | 230 | |

Cooling Water | m3/hr | N/A | N/A | 5 | 6.5 | 10 | 13 | 16 | 20 | 24 | 24 | 34 | 40 | 40 | 45 | 70 | |

Overall | mm | 1400 | 1600 | 2200 | 3600 | 3900 | 4500 | 4700 | 5200 | 6500 | 6500 | 7300 | 7300 | 7600 | 8000 | 8100 | |

Overall | mm | 1000 | 1100 | 1200 | 1750 | 2200 | 2300 | 2300 | 2200 | 2300 | 2300 | 3000 | 3000 | 3000 | 3200 | 4800 | |

Overall | mm | 1900 | 2100 | 2500 | 2850 | 3100 | 3100 | 3400 | 3800 | 3900 | 3900 | 4200 | 4200 | 4200 | 4600 | 4800 | |

Approximate | ton | 1 | 1.5 | 2 | 3 | 4.5 | 7 | 8.5 | 10 | 12.5 | 13 | 17.5 | 20 | 25 | 30 | 32 | |

</p

| Packaging Detail:Production vacuum freeze dryer/vacuum freeze dryer/pharmaceutical freeze dryerstandard sea shipping packing |

| Delivery Detail:5 months after order placed. |