pressure spray (cooling )dryer for food industry

| Condition:New | Type:Spray Drying Equipment | Place of Origin:China (Mainland) | Model Number:YPG |

| Voltage:380V 220V 415V | Power(W):50HZ 60HZ | Certification:ISO | After-sales Service Provided:Engineers available to service machinery overseas |

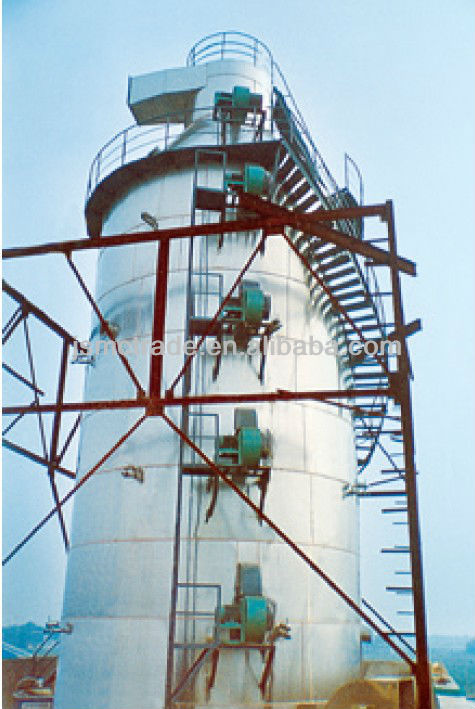

YPG SERIES PRESSURE SPRAY(COOLING)DRYER

Description

The material is sprayed into fine mist by nozzle on the top of tower. Follow the heat wind, the material is dried.

The machine‘s characteristic is high collection rate, no stick onto the wall, energy saving, high efficiency,

especially applicable for heat sensitive material. It’s widely used in food, dyestuff, chemical industry and so on.

scope of application

FOOD INDUSTRY : Fatty milk powder, protein, cocoa milk powder, substitute milk powder, egg white (yolk),

food and plant, oats, chicken juice, coffee, instant dissoluble tea, seasoning meat, protein, soybean,

peanut protein, hydrolysate and so forth.Sugar, corn syrup, corn starch, glucose, pectin, malt sugar,

sorbic acid potassium and etc.

MEDICINE : Traditional Chinese medicine extract, ointment, yeast, vitamin, antibiotic, amylase, lipase and etc.

PLASTICS AND RESIN: AB, ABS emulsion, uric acid resin, phenolic aldehyde resin, urea formaldehyde resin, formaldehyde resin, polythene,

poly-chloroprene and etc.

DETERGENT : Common washing powder, advanced washing powder, soap powder, soda ash, emulsifier, brightening agent,

orthophosphoric acid and etc.

CHEMICAL INDUSTRY : Sodium fluoride (potassium), alkaline dyestuff and pigment, dyestuff intermediate,

Mn3O4 compound fertilizer, formic silicic acid, catalyst, sulphuric acid agent, amino acid, white carbon and so on.

CERAMIC : aluminium oxide, ceramic tile material, magnesium oxide, talcum and so on.

OTHER : Calmogastrin, hime chloride, stearic acid agent and the cooling spray.

technical parameters

| spec | unit | 50 | 100 | 150 | 200 | 300 | 500 | 1000 | |||||||||||

| Water evaporation capacity | Kg/h | 50 | 100 | 150 | 200 | 300 | 500 | 1000 | |||||||||||

| Overall dimension(Ø*H) | mm | 1600*8900 | 2000*11500 | 2400*13500 | 2800*14800 | 3200*15400 | 3800*18800 | 4600*22500 | |||||||||||

| High-pressure pump pressure | MPa | 2-10 | |||||||||||||||||

| power | kw | 8.5 | 14 | 22 | 24 | 30 | 82 | 30 | |||||||||||

| Inlet air temperature | °C | 300~350 | |||||||||||||||||

| Product water content | % | Less than 5%,and 5 percent can be achieved | |||||||||||||||||

| Collection rate | % | >97 | |||||||||||||||||

| Electric heater | KW | 75 | 120 | 150 | When the temperature is lower than 200°C, the parameters should be calculated according to the practical condition | ||||||||||||||

| Electricity+steam | Mpa+kw | 0.5+54 | 0.6+90 | 0.6+108 | |||||||||||||||

| Hot air furnace | Kcal/h | 100000 | 150000 | 200000 | 300000 | 400000 | 500000 | 1200000 | |||||||||||

| Packaging Detail:according to the client specific requirement |

| Delivery Detail:within 30 days |