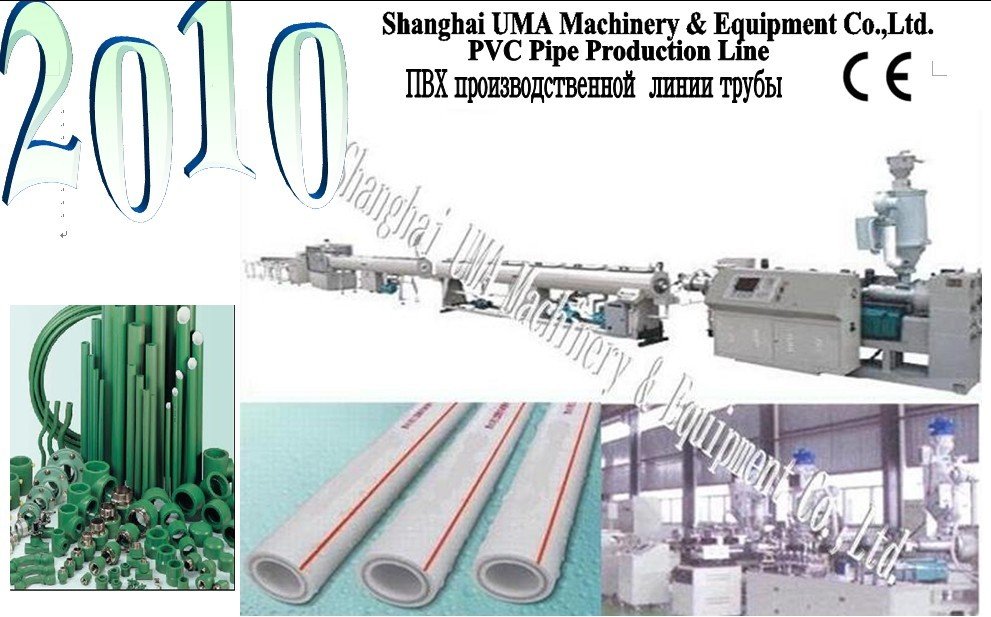

PPR Cold / Hot Water Pipe Line

CE, Diameter:16-160mm, Output:150-280kg/h, Production rate:2-15m/min, ppr pipe extruder extrusion production machine line - details see: https://www.machineto.com/ppr-cold-hot-water-pipe-line-10081707

| Type:Pipe Production Line | Pipe Material:PPR | Application:Other | Place of Origin:Shanghai China (Mainland) |

| Brand Name:UMA | Model Number:UMA-PPR160 | PPR Machine:PPR Pipe Machinery | PPR Pipe Line:PPR Pipe Machine |

| plastic pipe line:ppr plastic pipe line | pipe extrusion line:ppr extrusion line | PPR Pipe Machine Line:ppr pipe extrusion line | ppr pipe extruder:pipe production line |

| ppr plastic pipe machine:ppr plastic pipe machine line | PPR Machinery:Pipe Machine | ppr plastic line:ppr plastic machine | PPR Pipe Machine:ppr pipe extrusion line |

Main manufacturing:

1. Extrude foam and moulding production line;

2. All kinds of plastic pipe extrude production line;

3. Wood-Plastic extrude production line;

4. All kinds of plastic sheet and Plate Extruder Production Line;

5. Plastic recycling washing line;

6. Automatic blow molding machines;

7. All kinds of auxiliary plastic machine;

ppr pipe extrusion line ppr pipe extrusion line PPR Pipe Line

Process flow

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder → color code extruder → mould and calibrator → vacuum forming machine → cooling tank → haul-off machine → cutting machine → discharging rack

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder → color code extruder → mould and calibrator → vacuum forming machine → cooling tank → haul-off machine → cutting machine → discharging rack

Technical parameter

PPR pipe line

Diameter:16-160mm

Output:150-280kg/h

Production rate:2-15m/min

Installed power:100-150kw

Diameter:16-160mm

Output:150-280kg/h

Production rate:2-15m/min

Installed power:100-150kw

Advantages of PPR pipes:

1, non toxic and health. PPR raw materials for elements only carbon and hydrogen elements, there is no harmful toxic elements, and health , not only for hot and cold water pipes, can be used in clean drinking water systems.

2, thermal insulation. PPR pipe thermal conductivity coefficient of 0.21w/mk, only 1 / 200 to steel pipe.

3, good heat resistance. PPR pipe Vicat softening point of 131.5 degrees C. Maximum working temperature up to 95 degrees C, water supply and drainage to meet the construction specifications require in the use of hot water system.

4, long service life. PPR pipe in working temperature 70 degrees C, working pressure (PN) 1.0MPa conditions, the service life can be up to 50 years; at room temperature (20 degrees C) service life can be up to 100 years.

5, easy installation, connection.PPR has good welding properties, pipe, pipe fittings can be used hot-melt and fused connections, easy installation, the strength of its joints is greater than the strength of its own pipe.

6, recyclable materials. Waste PPR after clean, broken recycling can be used in the pipes, pipe fittings production. Recycling materials does not exceed the total amount of 10%, does not affect product quality.

1, non toxic and health. PPR raw materials for elements only carbon and hydrogen elements, there is no harmful toxic elements, and health , not only for hot and cold water pipes, can be used in clean drinking water systems.

2, thermal insulation. PPR pipe thermal conductivity coefficient of 0.21w/mk, only 1 / 200 to steel pipe.

3, good heat resistance. PPR pipe Vicat softening point of 131.5 degrees C. Maximum working temperature up to 95 degrees C, water supply and drainage to meet the construction specifications require in the use of hot water system.

4, long service life. PPR pipe in working temperature 70 degrees C, working pressure (PN) 1.0MPa conditions, the service life can be up to 50 years; at room temperature (20 degrees C) service life can be up to 100 years.

5, easy installation, connection.PPR has good welding properties, pipe, pipe fittings can be used hot-melt and fused connections, easy installation, the strength of its joints is greater than the strength of its own pipe.

6, recyclable materials. Waste PPR after clean, broken recycling can be used in the pipes, pipe fittings production. Recycling materials does not exceed the total amount of 10%, does not affect product quality.

Main Applications:

1, building hot and cold water systems, including central heating systems;

2, building heating system, including floor, wall and radiant heating systems;

3, can be directly used in purified water drinking water supply systems;

4, Central (concentration) air conditioning systems;

5, transfer or discharge of chemical media, such as industrial piping system.

Model number | PPR-16/63 | PPR-20/110 | PPR-50/160 |

Pipe diameter | 16-63mm | 20-110mm | 50-160mm |

Max output | 150kg/h | 150kg/h | 280kg/h |

Production rate | 5-15m/min | 2-12m/min | 2-10m/min |

Extruder model | UMA-65/33 | UMA-65/33 | UMA-75/33 |

Installed power | 100kw | 110kw | 150kw |

Center height | 1000mm | 1000mm | 1000mm |

Installation area | 35*3.0*2.0m | 38*3.1*2.2m | 38*3.2*2.2m |

| Packaging Detail:wooden cases |

| Delivery Detail:60 |