Powder metallurgy sintered garden tool spare parts manufacturer

| Place of Origin:Zhejiang China (Mainland) | Brand Name:HY | Model Number:359 | Material:metal powder(iron) |

| Density:5.0-7.2g/cm3 | Brand:HY, OEM is accepted | Application:furniture lock, security and protection | Quality:Strictly controlled in house |

| Delivery:About 30-45 days after order confirmed | Payment terms:T/T, L/C, Western Union | Type of Payment:30% deposit, balance against copy of B/L | Export port::Ningbo or Shanghai |

| Delivery way:By sea or by air/express |

Powder metallurgy sintered garden tool spare parts manufacturer

Features:

| 1 | High density and good strength |

| 2 | Good abrasion resistance & hardness |

| 3 | High precision within tolerance 0.02mm |

| 4 | Material: iron P/M parts (according to MPIF/JIS Z) |

| 5 | Competitive price with best service |

| 6 | Excellent OEM/ODM P/M manufacturer |

| 7 | ISO9001:2008 certificate |

Production Range:

| 1 Clutch Assembly | Clutch assemblies for chainsaw, lawn mower, brush cutter, hedge trimmer etc. |

| 2 Sintered Gears | Gears, Sprockets, Helical Gears, Bevel gears, Double Gears, Spur gear, Curved gear, Rack gear, Circular gear, Driving & driven gear, Medium gears, Planetary reducer gear, Planetary reducer gear parts, Ratchet wheel etc. |

| 3 Oil Bearings | Oil bearings, oilless bearings, bushing bearings, bearing shaft/block. |

| 4 Aluminum Die Castings | Aluminum die casting parts, aluminum shaft support for power tools |

| 5 Balance weigh, sprockets, ratchet, bushing, fastener,rotors,pulley. | Other sintered parts like bushings, sleeves, pistons, connecting rod, fasteners, nuts, rotors, stators, timing pulley, camshaft, toothed pulley, splined hub, shifting block, balance weight etc. |

| 6 Garden tool parts | Garden Tool parts for chainsaw, lawn mower, brush cutter, hedge trimmer, high sticks saw, wood working machine and other gardening machine etc. |

| 7 Power tool parts | Power Tool parts for electric drill, electrical hammer, angel grinder, electrical saw, electrical blower, cutting machine, jig saw, reciprocating saw etc. |

| 8Auto/motorcycle parts | Auto/motorcycle engine parts, gearbox parts, shock absorber parts, synchromesh gear hub, pressure side plate, striking fork, hydraulic valve pushrod seat, oil pump rotor, oil pump gear, oil pump flange,Pistons, Foot Valves, Rod Guide for Shock Absorber parts. |

| 9 Hardware tool parts | Hardware tool Parts and manual tool parts. |

| 10Farm machinery parts | Farm machinery parts/agricultural spare parts. |

| 11 Lock parts | Home Appliance Parts |

| 12Business and office equipment parts | Sand beach vehicle parts,fitness equipment handle, juicer parts etc. |

| 13 Sew machine parts | Textile machinery parts |

| 14 Other P/M structural parts | Other Iron/steel/alloy Powder metallurgy parts |

Products Application:

| 1 | Electric power tools parts |

| 2 | Garden tools parts |

| 3 | Hardware hand tools parts |

| 4 | Automobile and motorcycle parts |

| 5 | Household electronic appliance parts |

| 6 | Agricultural machinery parts |

| 7 | Metal & metallurgy machinery parts |

| 8 | Woodworking machine parts |

| 9 | Security & protection parts |

| 10 | Business and office machines parts |

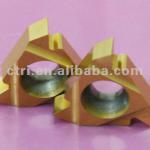

Series of Products Pictures:

Gasoline chainsaw clutch assembly

Lawn mower/brush cutter/grass trimmer clutch assembly

Sintered oilless/ oil bearing for garden tool spare parts

Sintered P/M spare parts for jig saw and reciprocating saw

Powder metallurgy sintered spare parts for garden tools and power tools

What is Powder Metallurgy?

| Powder Metallurgy (P/M) is a metal processing technology that converts metallic powder into useful engineering components of various shapes and properties. The major advantage of P/M is its ability to make highly complex, high precision parts at a fraction of the cost of competing technologies such as machining and investment casting. It has gained widespread popularity in a wide array of applications from automotive seat belt components, electric contacts, soft magnetic cores, to a variety of structural applications. |

| Powder Metallurgy uses sintering process for making various parts out of metal powder. The metal powder is compacted by placing in a closed metal cavity (the die) under pressure. This compacted material is placed in an oven and sintered in a controlled atmosphere at high temperatures and the metal powders coalesce and form a solid. A second pressing operation, repressing, can be done prior to sintering to improve the compaction and the material properties. |

Powdered Metal Materials Properties:

| 1 | Dry working condition, provides maintenance free operation. |

| 2 | Can be applied in widely temperature -200 to +300 |

| 3 | Suitable for high static and dynamic load |

| 4 | With low and smoothly coefficient of friction and without stick-slip effects |

| 5 | Suitable for dirt, impact and edge load |

| 6 | Good thermal conductivity property |

| 7 | Suitable for reciprocating, rotating and oscillating movement with start frequency and difficulty to form oil film occasions |

| 8 | With lower wear rate and long life service |

Advantages of Powder Metallurgy:

| 1 | Various material selection and energy saving |

| 2 | Minimum secondary machining process |

| 3 | Cost saving for complicated shaped product |

| 4 | Meting any dimensional product requirements |

| 5 | Improving dimensional precision |

| 6 | Achieving required microstructure with various material selection |

| 7 | Supreme surface treatment |

| 8 | Improving hardness and endurance by adequate heat treatment process |

| 9 | Manufacturing uniform products |

| 10 | Suitable for self-lubricants & filters for minute porosity |

| 11 | Good for mass production |

Powder Metallurgy production process:

Quality Control Flow:

Company Detailed Descriptions:

1. Zhejiang Xinhe Powder Metallurgy Co., Ltd is a professional powder metallurgy & aluminum die casting manufacturer.

2. P/M process: mixing--compacting--sintering—heat treatment--resizing--cleaning--vacuum oiling—packing

3. Material: carbon steel, copper steel, copper molybdenum steel, alloy.

4. Production equipment:

a. Hydraulic press with 200T, 160T, 100T, 60T, 50T, 25T, 20T, 10T, 6T;

b. 2 lines of high-temperature mesh belts furnace;

c. 1 set of heat treatment furnace

d. Other resizing machines like drilling machine, grinding machine, CNC machine, polishing machine, plating machine etc.

5. All-round testing equipments: 2.5d profile projector, Rockwell hardness tester, Metallographic measuring instrument, gear beating detector, beat monitor, digital push & pull tester.

6. High precision within tolerance 0.02mm, 100% good quality with competitive price, good abrasion resistance, high density & hardness, high efficiency, energy saving.

7. Application: our products are widely used in garden tools, power tools, automobile, motorcycle, farm machinery, home appliances, business and office equipments and many other fields.

8. Supply ability: 2000tons/year

9. Packaging: plastic bag in white box and export carton box with pallet or as per customers’ requirements.

10. Short delivery time: within 1 month after receiving your payment.

11. Export Port: Ningbo/Shanghai, China

12. Payment terms: T/T, Western Union

13. Certificate: ISO9001:2008

14. ODM/OEM acceptable, we can make the products according to your drawings or samples.

Pictures for compacting workshop

Pictures for sintering workshop and high temperatue mesh belt furnace

Pictures for heat treatment furnace

Pictures for tooling workshop

Order guidings

| 1 Order Procedures: | Select our listed item or send us your designs or samples. Send us LOGO in CDR or AI format if you want items imprinted, we will make sample for approval. Start all products manufacturing, packing and final inspecting and shipping. |

| 2 Sample policy: | Samples will be provided according to customized requests. Sample cost will be charged in a certain amount according to the value of products. Sample cost could be refunded according to the agreement between both supplier and buyer. This condition would listed on the quotation. Sample cost will be including the courier charge for delivery. |

| 3 Shipping: | Destination: We are able to ship goods to every corner of over the world. Arrangement: We would arrange booking in first 7 days before shipment, and ship after balance cleared. Shipping methods: 1) Ocean shipping, 2) Air cargo, 3) International courier shipping, which is depending on the cargo conditions. Appointed forwarder: If the forwarder is appointed and shipping companies for shipment, we will follow up the instruction. Appointed shipping line: If the shipping line is appointed, we arrange booking for this line exclusively for shipment. Door-to-door shipment: We could arrange door-to-door shipment depending on your supply of collect account accordingly. After shipping: We will prepare all documents for custom clearing and cargo taking-out. |

| 4 Payment: | Order payment: We accept T/T, Western Union, MoneyGram, Bank Transfer etc. Sample payment: We accept payment via Escrow by following payment methods Payment term: 30% deposit prepaid and 70% balance will be paid before shipment. For security reasons, we will only offer account with stamped or signed. |

| 5 Warranty and returns: | We provide 1 year warranty. We test every product before ship to guarantee 100% working. If this item is defective upon receipt, customer should put forward within 7days from the date of receipt for exchange new one(s). (The return item(s) should include all original items undamaged in re-salable condition). Once we get the return item(s), we will send new qualified one(s) back to you as soon as possible. Our warranty does not extend to any products that are physically damaged or that are not under normal operating conditions as a result of misuse or improper installation on the buyer's part. |

| Packaging Detail:Plastic bags into carton box, or as per your requirement. |

| Delivery Detail:About 30 days after order confirmed |