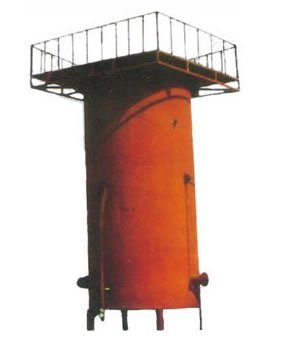

Powder dryer

| Type:Flash Drying Equipment | Place of Origin:Henan China (Mainland) | Brand Name:HD | Model Number:TDLS Series |

Powder dryerfunction is introduced:

Cylindrical vertical in chapter is made for the condition, facing the current coal drying furnace widespread investment, covers an area of big, under the situation of high failure in industrial coal drying characteristics, use low gravity principle, great air-delivery and the industrialization of research design, test and product upgrading upgrade, operation mode of a lasting for several years in several stages, and success. In product innovation, fully embodies the applicable, expand efficiency, reduce cost, improve quality. Safety and protection of the environment is used for drying of coal production.

Vertical dryer (cylindrical vertical) drying principle and characteristics:

After ", "conveyor belt conveyor by polo, the cloth to top device to top the uniform distribution section. In its orbit of coal by gravity slow down on one side to side with the wind moving heat. Type of coal moisture evaporate by winds and random away. After two hours of coal to the evaporation process fully dry. Economic characteristics: and now universal backflow drying oven, investment lower than 1/2, The area is 1/5-1/3, Energy consumption and operation cost greatly reduced. Use: this product is good matching technology, in line with other equipment and automation. Equipment, convenient operation, easy maintenance. Drying furnace body no mechanical components, daily without maintenance. Continuous operation, high efficiency and production. Give a large fertilizer use coal rods, drying, and achieved good results: gasification furnace in coal rods, moisture to 3%, gas production increased obviously. Lots of managing manpower, reduce the labor intensity, Save the venues, expand the production.

Cylindrical vertical quality features:

By adding machine pressure molding, usually in 12-14 moisture. After drying, the moisture content is reduced to 2-4%, can satisfy the intensity and storage requirements. On this basis, the adaptability again after reforming, moisture can drop to less than 1.5%; Also can dry pre-reduced ore, coal rods particle etc.

Vertical dryer basic technical parameters

Model | Primary moisture | Final moisture | Output (t/h) | standard coal consumption (kg/t) | current drain (kw/t) | weight | ||

| clay | slag | coal | ||||||

| TDLS-2012 | 25% | 2% | 67.8 | 1012.6 | 810 | 2025 | 23 | 17 |

| TDLS-2014 | 25% | 2% | 78.6 | 1214 | 912 | 1823 | 1.82.6 | 19 |

| TDLS-2016 | 25% | 2% | 811 | 1316 | 1014 | 1722 | 1.62.2 | 21 |

| TDLS-2216 | 25% | 2% | 912 | 1517 | 1215 | 1620 | 1.52.1 | 26 |

| TDLS-2218 | 25% | 2% | 1013 | 1618 | 1416 | 1418 | 1.52.0 | 28 |

| TDLS-2220 | 25% | 2% | 1113.8 | 1720 | 1517 | 1316 | 1.41.8 | 30 |

| TDLS-2222 | 25% | 2% | 1315 | 1923 | 1619 | 1314 | 1.41.6 | 32 |

| TDLS-2516 | 25% | 2% | 1722 | 2228 | 1826 | 1316 | 1.41.8 | 38 |

| TDLS-3018 | 25% | 2% | 2227 | 3445 | 2332 | 1418 | 1.52.0 | 45 |

TDLS-3210 | ||||||||

| 25% | 2% | 2532 | 3852 | 2639 | 1720 | 1.82.3 | 48 | |

| Packaging Detail:negotiable |

| Delivery Detail:20 days after advanced |