Popular use in many countries C Channel/steel purlin forming machine

| Type:Steel Frame & Purlin Machine | Condition:New | Production Capacity:15sets one month | Place of Origin:Hebei China (Mainland) |

| Brand Name:ShiBo | Model Number:C purlin | Voltage:can do based on client's requirement | Power(W):15KW+15KW |

| Dimension(L*W*H):8m*1.35m*2.2m | Weight:7 tonnes | Certification:CE and ISO certifaction | Warranty:one year |

| After-sales Service Provided:Engineers available to service machinery overseas | Brand:ShiBo | Product Warranty:12 month | Product Quality:we provide the technical support for whole life of the machine |

| Type of the machine:we can design it as customers detailed drawing | Color of the machine:we can aslo painting it as customers request | Certifaction:CE and ISO | Drive way:By chain |

| Control system:PLC control |

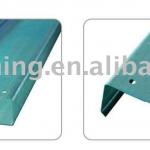

Popular use in many countries C Channel/steel purlin forming machine

1,Advantages of the roof making machine

| advantage of the machine | 1. Low noise 2. Stable 3. Easy to control |

| advantage of the tiles | 1. High strength 2. Durable 3. Elegant 4. Easy to install |

2, Main technical dates:

Flow chart

Decoiler ---> leveling ---> roll forming---> hole punching (optional) ---> calibrating

----> automatic cutting ----> output

Main Technical Data(Twist) | |

| Forming size: | 8000mm*2000mmx1400mm |

| motor reducing gears | 15kw |

| weight | 5T |

| Big frame | 350 H steel |

| Axis | φ80 |

| wheel | Gr15quench |

| Made board | 20mm |

| chain sprocket | 2.0inch |

| Forming speed | 8-9m/min |

| Forming thickness: | 1-4mm according to user's need |

| Roll stations: | 15 rows |

| Motor power: | 15-30kw |

| Hydraulic power: | 5.5kw |

| cutting: | Hydraulic cut |

| Control system: | PLC automatic control |

| Un-coiler: | Manual or hydraulic |

| Run-out table: | Unpower or pneumatic |

Hydraulic shearing:

| Material of blade | Cr12,heat treatment 60-62°C |

| Shearing system | (1) It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pumps drive the cutter machine to begin the cutting job. (2)Adopt cutting after roll forming, will assure the best accuracy for product length and straightness, the length can be adjust according to your detailed requirement. (3) Cutting thickness : 0.35-0.8mm Length to lerance: ±2.0mm (4)The system includes a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And two sets of electromagnetism valves. Power of the oil pump: 3kw Hydraulic oil :40# (5) Hydraulic station: one set, provide the power for hydraulic cutting system, power use 3KW. |

Electrical control system

| Screen display | 5.7 inches Tai Da touch screen |

| Main computer control cabinet | (1)It adopts industrial computer to control. In the whole line, there will be one control consoles to control all units. All control consoles adopt PLC controller + inverter + LED touch screen ( Taiwan Taida),It contains liquid crystal screen, programmer, transformer for the electronic machines and kits of every part. Transducer brand is EURA (2)The target piece’s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use. Processing precision : within 1.00mm (3) provide Chinese and English language screen. |

3, Certifaction:

4 Product show:

| Packaging Detail:main body of the machine naked into the containers, covered with plastic film, spare parts in the wooden box |

| Delivery Detail:within 30 working days after received deposit |