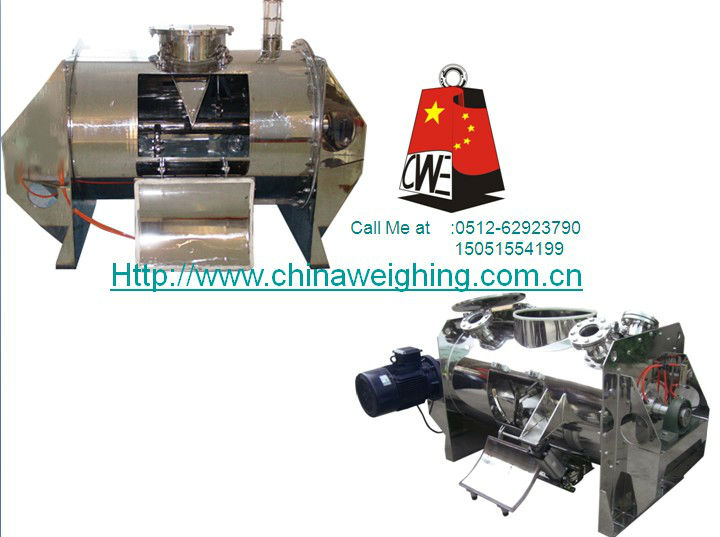

Plough Mixer

| Condition:New | Application:Powder Mixing,Food, Chemical, Powder Mixing | Place of Origin:Jiangsu China (Mainland) | Brand Name:CWE |

| Model Number:PM | Voltage:220V-440V 50hz/60Hz | Power(W):3-75Kw | Features:High Efficiency, Easy access |

| Certification:SGS | After-sales Service Provided:Overseas service center available | Power:3Kw-75Kw | Driven Type:Electric |

| Automatic Grade:Automatic | Function:Mixing |

About our Mixers

AWE mixers are available in a variety of shapes and sizes to suit the needs of different operations. The Plough mixer is built to meet the most demanding requirements of quality and long term performance. Meticulous attention to detail in specification and production of mixing systems is vital, because even small alterations in design and fabrication may translate to an increase in production. Each AWE Plough Mixer includes plows and choppers to accelerate the blending cycle and provide a well balanced lateral and radial transfer of ingredients.

Main features include:

All interior corners have a radius to prevent material collecting and creating problems during discharge or cleaning

Clearances are meticulously controlled

All internal welds are ground to a smooth surface

A manually activated Slide Paddle Valve or Slide Knife Gate Valve are the most common options for an AWE Plough Mixer. If your operation has a vacuum or pressure operation, a Spherical Disc Valve, Knife Gate Valve or Ball Valve provide a positive seal. If no dead space is allowable, a Flush Plug should be included.

Advantages:

Maximum mixing homogeneity

Mixing of abrasive materials

Minimum wear/low maintenance

Easy access

Minimum residue

Possibility of bomb bay discharge

As Standard

Seals:

The mixing result and the subsequent cleaning depend on the seal quality at either end of the shaft. AWE offers a wide range of sealing devices to suit a variety of materials. The standard sealing structure is a stuffing box style seal, also known as a TEFLON seal. After a period of use, this seal should be serviced or adjusted. As an alternative, the dynamic seal has a long term sealing effect and is especially suitable for powder and liquid applications.

Feeding Inlet on the Body Cover:

Two types are available:

Type A: Used in the whole mixing/blending process. In order to connect the feeding devices (augers, pneumatics etc) the connecting unit is custom designed to fit your new or existing system.

Type B: Used in manual feeding. In order to operate and clean within the body of the mixer, feeding inlets or doors can be designed that are tailored to the needs of your operation.

Discharging

There is a discharging valve at the bottom of the mixer body. When mixing different types of materials, the flap valve is supplied as standard, with options for a ball valve, butterfly valve, slide gate valve with further options for a manual, air driven or electrically driven function.

Temperature Control

When heating, cooling or heat preservation is needed, the system can include a jacket. Filled by air circulation and heat conduction, it is not suitable for a high pressure environment. Heat conduction can be supplied by water (limited by 90 degrees) or oil (limited by 300 degrees). The jacket can coordinate both the external heating system and the expulsion system. This system is best suited to a mixing process requiring large quantities and infrequent changes of product due to cleaning difficulties with the jacket in situation.

Technical Specifications

| Packaging Detail:Wooden Case |

| Delivery Detail:30 days |