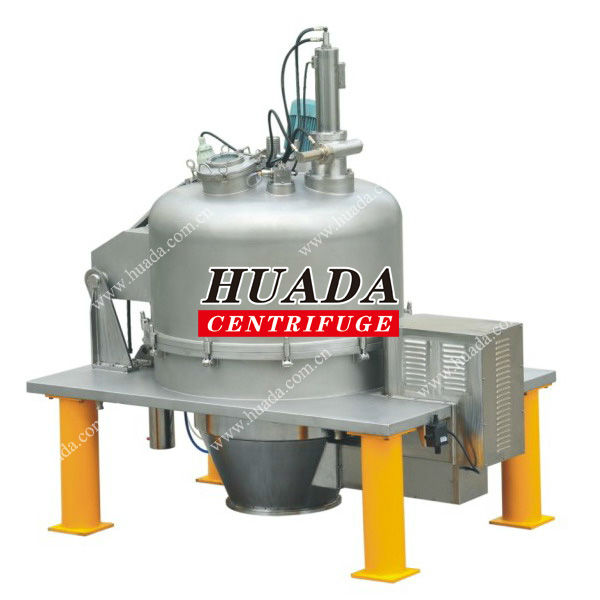

PLD Pull-bag Bottom Discharge Centrifuge

| Condition:New | Type:Centrifuge | Product Type:solid-liqudi | Place of Origin:Jiangsu China (Mainland) |

| Brand Name:huada | Model Number:PLD | Voltage:380V | Power(W):7.5-37KW |

| Weight:2200-9500KG | Certification:ISO9001 | Warranty:1year | After-sales Service Provided:Engineers available to service machinery overseas |

| centrifugal type:basket centrifuge | discharge:scraper bottom dischareg | operation:automatic batch operation | machine control:PLC control |

| screen touch:optional | MOC:Stainless steel |

PLD Bag-pulling automatic Bottom Discharge

Centrifuge

Process | Applications | Design Features | Configurations| Technical Parameters

Process

PLD series bag-pulling bottom discharge scraper centrifuge is a type of new product with fully independent intellectual property independently developed by us. This series centrifuge retains such primary functions offered in the LGZ series as the solid-liquid separation and scraper discharge, and adds such function as to remove the residual solid cake by pulling filter cloth with the removal rate higher than 99%. PLD series avoids crossing and mixing of different batches of separated products, and also eliminates the effects of the residual solid cake on the basket wall.

Applications

It can be widely used to separate the suspension containing particles, but also fibers, especially the highly sticky, containing micro particles, poisonous and flammable materials, like antibiotics, vitamins, and minerals, salts, gourmet powders, foodstuff additives, amylum, sugar, chemical flavors, thiamin, plasters, sodium sulfate, bluestone, potassium chloride, borax, dyestuffs, pigment, resin, pesticides, and environmental protection. The centrifuge is highly automated, has large capacity and can be remote-controlled.

DesignFeatures

In addition to all main features of the LGZ series centrifuge, the PLD series centrifuge features as follows:

♦ Discahrge method

1.Removing the residual solid cake by bad-pulling method. Eliminate all solid cakes left over the process of scraper discharging through reciprocal movement of the pneumatic pulling bag deice.

2.Fully-enclosed discharge hopper design separating the material from the driving components of the centrifuge

♦Filter cloth changing

Design of removable lip ring in the basket with reliable self-locking, which is easy for changing the filter cloth.

Configurations

Optional configurations

♦External construction: big hinged cover, fully hinged cover and flat cover

♦Feed type: inclined feed disk, side feed and cake layer controller

♦Scraper discharge: Pneumatic, hydraulic and liquid-phase skimming disc

♦Motor drive: Common motor, inverter-duty motor and explosion-proof motor

♦Safety protection: Nitrogen protection system, explosion and vibration protection, temperature protection, electric-mechanical interlocking, rotation monitoring and overload protection.

♦CIP system: Cleaning ball and spray pipe

♦Nitrogen protection system: Automatic control device, hydraulic sealing device and gas-liquid separator.

Technical Parameters

Item | Models | |||

| PLD800 | PLD1000 | PLD1250 | PLD1600 | |

| Basket Dia(mm) | 800 | 1000 | 1250 | 1600 |

| Basket Volume(L) | 100 | 175 | 380 | 775 |

| Max.Load(kg) | 125 | 235 | 380 | 1050 |

| Max.Rotating Speed (rpm) | 1200/1500 | 1050/1300 | 970 | 850 |

| Centrifugal Force | 1008 | 620/950 | 658 | 647 |

| Motor Power(kw) | 7.5/11 | 11/15 | 22 | 37 |

| Dimension(L*W*H) (mm) | 1900*1250*2300 | 2100*1500*2250 | 2450*1800*2047 | 3000*2200*2700 |

| Weight | 5500 | 8500 | 13000 | 20000 |

Key words: centrifuge, centrifuge machine, basket centrifuge

Production Process of HUADA Centrifuge

HUADA Quality Control

HUADA Package & Delivery

| Packaging Detail:1. Poly film packing for centrifuge machine2. Wood carton for electrical cabinet |

| Delivery Detail:45 to 60 days |