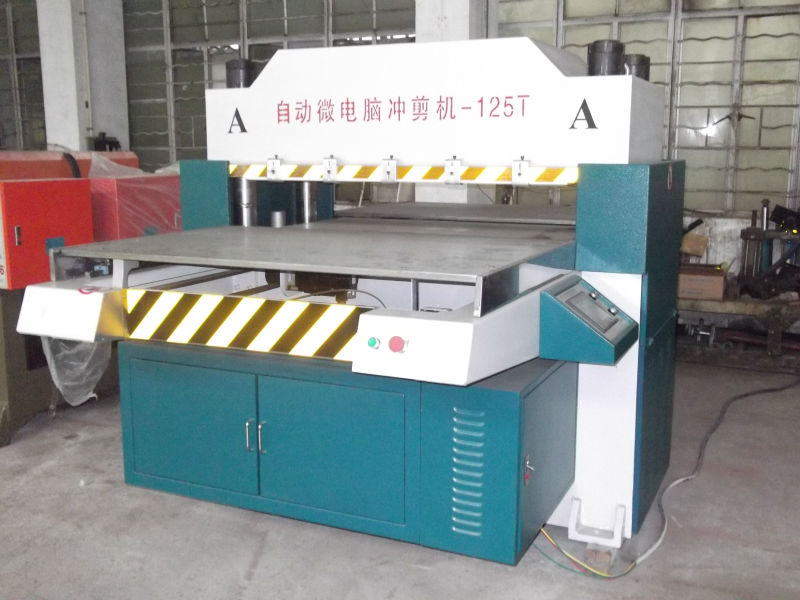

Plastic vaccum forming punching machine

Plastic vaccum forming punching machine, This machine is suitable for cutting the skins ,plasticsheet ,nylon cloth ,foam , - details see: https://www.machineto.com/plastic-vaccum-forming-punching-machine-10337315

| Condition:New | Application:feeding | Place of Origin:Guangdong China (Mainland) | Brand Name:LS |

| Model Number:LS-100 | Certification:ISO9001:2008 | Warranty:12 months | After-sales Service Provided:Engineers available to service machinery overseas |

| weight:5.2t | Cutting pressure:125t |

Plastic Vaccum forming punching machine

Technical parameter

| Model | LS-125 |

| Cutting pressure | 125T |

| Available cutting area(mm) | 1250 X800 |

| Area between pillars(mm) | 1400 X800 |

| Stroke(mm) | 220 |

| Host motor power | 7.5Kw |

| Net weight | App.5200Kg |

| Voltage | 380V,50Hz, three-phase, four-wire |

| Size | 3000X1800X1650mm |

| Production rate | 5-14molds/min |

- Computer control system and H.M.I, all make the operation easy, quick and accurate.

- Double oil cylinder, precise four-pillar self balancing linkage mechanism to make sure consistent cutting depth.

- Hydraulic cutting adopt manual type, only need to press the button one time, the sheet can be cut completely. The machine sets with emergency stop device to make sure for personal safe.

- Differential design. Top mould table moves downward at high speed at the beginning and then slow down when about to cut, which avoid cutting size error at different layer.

- When cutting environmental protection material such as PET,OPS,EPE,ABS, there is no fail cutting or rough selvedge.

- Cutting pressure fine regulating device allows user to get best cutting pressure easily. The machine can much reduce wastage on mould and sheet because of its accurate degree of balance.

- Auto Lubrication makes sure precision and improves endurance of the machine.

- Special designed cooling system and rotation encoder device make sure accurate location of mould.

- The machine can work with single size or double sizes auto sheet feeding device to increase product rate to two or three times.

- PLC control and H.M.I make operation easy and convenient.

- Adopt anti-noise technology to reduce noise when running.

- Cutting depth is set by inputting number.

| Packaging Detail:cover with film |

| Delivery Detail:30days |