Plastic Compounding and Granulating Line, Plastic Granulating Line, Plastic Pelletizing Line

| Condition:New | Type:Granulating Production Line | Capacity:300-400kg/h | Place of Origin:Shanghai China (Mainland) |

| Brand Name:CISSCO | Model Number:SAT65 | Material:PP/PE | Screw Design:Double |

| Voltage:380v | Power:132KW | Dimension(L*W*H):20m*2m*2m | Weight:20 tons |

| Certification:CE | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas | Color:optional |

Plastic Compound Pelletizing Line

What’s plastic material modifying?

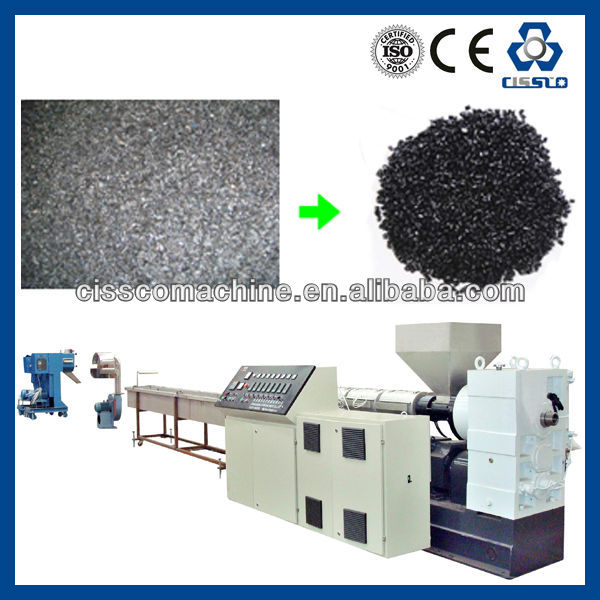

Plastic modifying is through physical, chemical and mechanical method to improve the comment resin’s property to meet the special demand on the special environment. Modified plastic is widely applied, high technical and high profit industry. And the plastic modifying technical-filling, mixing and enhance have widely and deeply applied in most of plastic resin and production processing.

How to modify the plastic material?

Compounding pelletizing-add the special additives to the common resin, and compound the mixture then through the double screw extruder to plasticizing. The material will gain the special property to meet the special demand.

I. Main technical specifications of pelletizing line

1)Product task

TPE Compound 1: SBS, PS, paraffin oil, fillers, stabilizers.

TPE Compound 2: SEBS, PP, oil, fillers, stabilizers;

2)Output and main extruder type

Output: 300--400kg/hr (difference up to specific formula);

Main extruder type: SAT65 co-rotating twin screw extruders;

3)Flow chart description

Premixing -> volumetric feeding-> twin screw compounding -> melt filtering ->water ring palletizing-> dewatering -> classifier

II. Scope of delivery of pelletizing line

| No. | Denomination of the delivery | Qty | Spec. and model |

| 1.0 | Raw materials dealing and feeding units | ||

| 1.1 | High speed mixer | 1 set | 300L |

| 1.2 | Loader | 1 set | |

| 1.3 | Main feeder | 1 set | |

| 2.0 | SAT65 compounding unit | ||

| 2.1 | SAT65 twin-screw extruder | 1 set | Main motor 132KW |

| 2.2 | Vacuum unit | 1 set | 2.2KW |

| 2.3 | Melt filtering system | 1 set | Hydraulic |

| 3.0 | Water ring pelletizing line | ||

| 3.1 | Extrusion die plate | 1 set | Φ2.4mm, 60holes |

| 3.2 | Water ring pelletizer | 1 set | |

| 3.3 | Water circulation system | 1 set | |

| 3.4 | Centrifuge dewater | 1 set | |

| 3.5 | Classifier | 1 set | |

| 4.0 | Control cabinet | 1 set | |

| 5.0 | Spare parts |

III. Pictures of delivery of pelletizing line

| Packaging Detail:painted with anti-corrosion oil, and covered with plastic film. |

| Delivery Detail:3 months |