PIPE PREFABRICATION PRODUCTION LINE(CONTAINERIZED);PIPE SPOOL FABRICATION PRODUCTION LINE(MOVABLE)

| Type:Pipe Production Line | Pipe Material:Stainless Steel | Application:Energy Supply Pipe | Place of Origin:Shanghai China (Mainland) |

| Brand Name:shanghai qianshan | Model Number:TPPPL-24A | Sturcture Type:Containerized Type Piping/ Pipe Spool Fabrication System | Cutting & Beveling:Cold cutting & beveling; Thermal cutting & beveling |

| Beveling Speed:<5Min / Two Bevels | Conveying Speed:2-20M/Min | Welding Process:TIG,MAG,MIG,SAW | Welding Type:Automatic Welding |

| Automatic Welding Rate:>60% | Voltage:380V/415V/440V-3Ph | Color:Green or as per request | Usage:Pipe Prefabrication |

Pipe Prefabrication Production Line (Containerized Type ); PIPE SPOOL FABRICATION PRODUCTION LINE (Movable Type)

Model: TPPPL-24

Performance Features:

1. Basic Configurationa:

Containerized Type Piping/ Pipe Spool Fabrication System

Many Sets of Pipe Cutting & Beveling Machining Workstation.

Many Sets of Mechanical Pipe Fitting Up Workstation

Many sets of Piping Automatic Welding Workstation

Many Set sof Logistics Transport System or Conveying Sstem.

A Set of Steel Structure Pipe Racks.

2. Production Efficiency: Eextremely high ( Hoisting by overhead traveling crane, Beveling by

High Speed Pipe Cutting and Beveling Machine and Welding by Automatic Welding Station)

3. Applicable Industries:OIL & GAS, OIL REFINERY FACILITIES, PETROCHEMICAL, ONSHORE & OFFSHORE,

CHEMICAL ENGINEERING, NUCLEAR POWER PLANT, SHIPBUILDING, POWER PLANT, ENERGY, AEROSPACE.

Especially suit for field pipe prefabrication.

4. Production Capacity: 20, 000~150, 000 DI/ month (or depend on filed size or machines config),

reduce manpower input, improve automation level & efficiency, and save much more cost.

Technical Parameter:

| Technical Description | Standard Type : | Custom-Made : |

| Suit for Pipe Diameter: | 2"-16"/24"/32" | 2"-40"/48" or above |

| Pipe Wall Thickness: | 3-80 (mm) | 3-80 (mm) |

| Conveying Speed: | 2-20 m/min | 2-20 m/min |

| Welding type: | Automatic root pass, fill in & final pass | Automatic root pass, fill in & final pass |

| Welding Process: | TIG/MIG/MAG/SAW | TIG/MIG/MAG/SAW |

| Automatic Pipe Welding Rate: | ≥60% | ≥60% |

| Pipe Cutting & Beveling Speed: | ≤5min/ two bevels(8"Sch40) | ≤5min/ two bevels(8"Sch40) |

| Pipe Spool Prefabrication Ratio: | ≥60%-80% | ≥60%-80% |

| Piping Design Software: | PDSOFT 3D Piping | PDSOFT 3D Piping |

| Process Management Software: | PDSOFT SPFMS | PDSOFT SPFMS |

Welcome to you visiting our factory or project site at any time in Shanghai City, P.R.China; For more detail information please contact us. Or browse our website: www.qs-pipe.com www.qiansh.com www.jsqianshan.com Thank you !

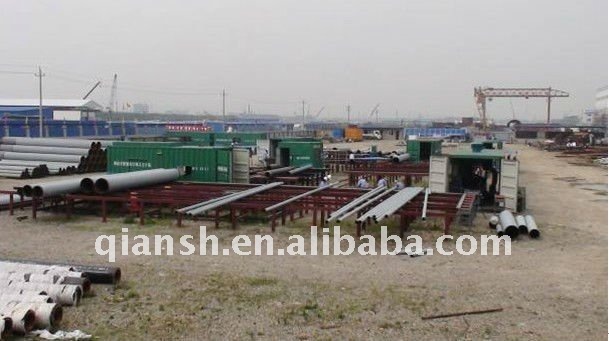

Photos:

| Packaging Detail:Stuff into container consist of workstation |

| Delivery Detail:30 workdays |