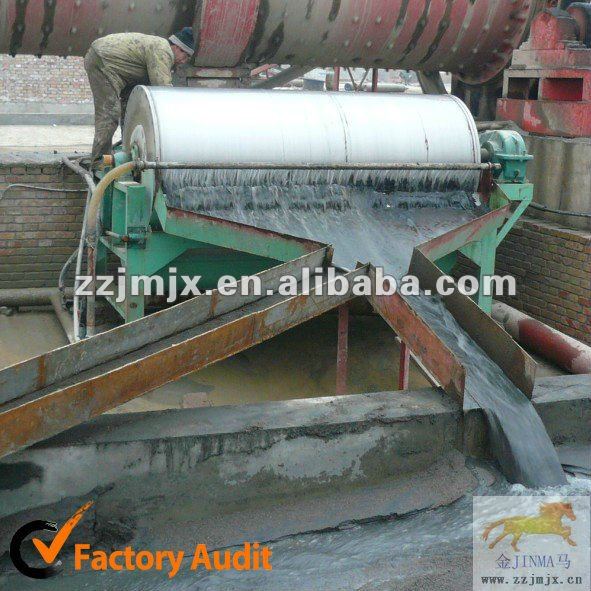

permanent Drum Magnetic Separator

| Condition:New | Type:Magnetic Separator,Separator | Production Capacity:90% | Place of Origin:Henan China (Mainland) |

| Brand Name:Jinma | Model Number:wet and dry | Voltage:380V to 440V, or as request | Power(W):5.5 KW |

| Dimension(L*W*H):2600x1300x1500 | Weight:6000 KG | Certification:CE, SGS, BV, ISO | Warranty:2 years |

| After-sales Service Provided:Overseas service center available | certificate:ISO9001:2008, CE, SGS, BV, QS | guarantee:2 years (wearing parts exclude) | motor:Chinese famous brand or as request |

| color:As required | Application:beneficiation, mineral processing, ore upgrading, cement making, etc. |

-Drum Magnetic Separatordirect from state-own factory

-ISO, BV, CE, SGS certificates

-Exported to over 30 countries

-Competitive price

Working Theory ofDrum Magnetic Separator:

The mineral slurry flows into the cellthrough box feeder, the mineral particle is loose under the function of waterflow of feeder water pipe when they flow into the cell. Affected by magneticfield, the magnetic particle swarm together and form magnetic cluster or chain.With the magnetism of mineral slurry, the magnetic cluster or chain movestoward the magnetic pole, and is absorbed to the cylinder. Because of thepolarity of magnetic pole, the revolving directions alternate constantly, and remainfixed when it is working. When the magnetic cluster and chain go round andround along with the cylinder, the mingled gangue and other non-magnetic orefall down due to the mixing phenomena produced by alternation of magneticpoles, and it is concentrate that is absorbed to the cylinder surface. Theconcentrate moves to the end of magnetic system where the magnetism is weakestalong with the revolving cylinder, and is discharged into concentrate tank bythe current ejected by the discharging-ore pipe. The non-magnetic or weakmagnetic remained are discharged along with the mineral slurry, and they aregangue.

Drum Wet magnetic separator

| Model | capacity(t/h) | Magnetic intensity (Gauss) | power(kw) | weight(T) |

| CTB600×900 | 8-15 | 1450 | 1.1 | 0.91 |

| CTB600×1800 | 15-25 | 1500 | 2.2 | 1.34 |

| CTB750×1200 | 25-30 | 1550 | 2.8 | 1.49 |

| CTB750×1800 | 30-45 | 1550 | 3 | 2.05 |

| CTB900×1800 | 35-60 | 1550 | 4 | 3 |

| CTB1050×2400 | 55-90 | 1550 | 5.5 | 5 |

| CTB1200×3000 | 80-150 | 1550 | 7.5 | 7.8 |

| CTB1500×3000 | 120-200 | 1550 | 11 | 9.6 |

Dry magnetic separator

| Model | 7518 | 9018 | 1018 | 1021 | 1024 | 1230 | 1530 |

| body (diameter*length)mm | 750×1800 | 900×1800 | 1050×1800 | 1050×2100 | 1050×2400 | 1200×3000 | 1500×300 |

| Capacity(t/h) | 4050 | 4555 | 100120 | 125145 | 130-180 | 150-220 | 170-250 |

| Feed size(mm) | 08 | 08 | 08 | 010 | 010 | 0-10 | 0-10 |

| power(KW) | 3 | 4 | 5.5 | 5.5 | 5.5 | 7.5 | 11 |

| Ore humidity (%) | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| Rotary speed(r/min) | 34 | 30 | 24.5 | 24.5 | 24.5 | 21 | 18 |

| Magnetic intensity(Gauss) | 2000-8000 | 2000-8000 | 2000-8000 | 2000-8000 | 2000-8000 | 2000-8000 | 2000-8000 |

...

| Packaging Detail:Standard packing, Seaworthy packing |

| Delivery Detail:In 10~15 working days after the down payment |