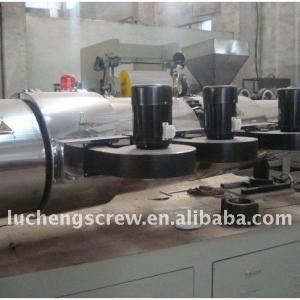

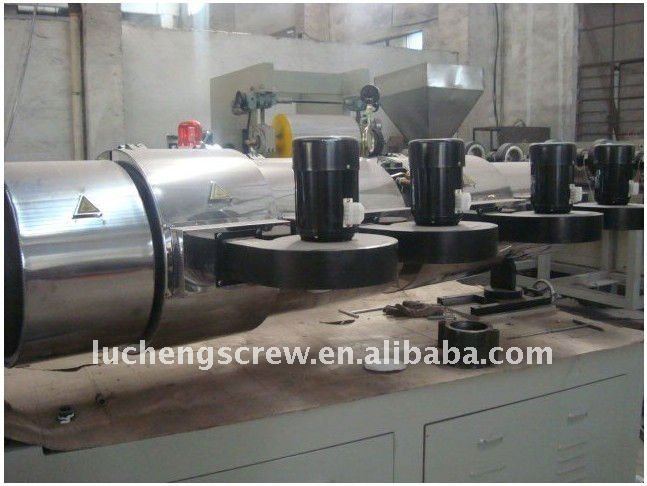

PE PVC twin screw plastic machine extruder

| Place of Origin:Zhejiang China (Mainland) | Brand Name:lucheng | Model Number:LC036 | Model/Specification:SJZ92 |

| Screw diameter(mm):92/188 | Max rotation speed(r/min):36 | Torsional moment of screw (Nm):32000 | Main motor(KW):110 |

| Barrel Heating Power:73.1 | Production capacity:750 | Center height(mm):1200 | Dimension:6725*1550*2814 |

PE PVC twin screw plastic machine extruder

Specifications

Conical double screw extruder:

1.Diameter:45-92mm

2.Max capacity: 750kg/h

3.Certificate:CE,ISO

4.Extruder model: LU45-92

Model lucheng series twin conical screws extruder is a kind of special equipment for extruding of PVC powder. With different sorts of molds and auxiliary machines,it can produce all sorts of PVC plastic pipe material,profiled material,plate material,sliced material,bar material and granulation.

The screw has applied oil cooling system. Barrel is cooled by special wind cooling system. The system has applied special computer control. According to custimers requirements.most reasonable screw can be made so as to achieve best plasticity state and material quality. The screw is made by high precision special digital screw miller,extruding property can be highly harmonizedl. It has firstly intruduced advanced technique of producing screws with variable pitch and depth,so that the material can be more softly sheared and cut. The distribution box is specially designed,pell force bearing is fully imported,the drive life span can be prolonged. It can bear larger extruding pressure. The electrical system has mainly applied imported parts,it has multiple alarm system,there are few problems which can be easily eliminated. The cooling system has applied special design,heat emission area is enlarged. The cooling is rapid,temperature control tolerance canbe ±1.

Main technical data

| Model | QF35 | QF50 | QF70 | QF90 | QF100 | QF120 |

| Cylinder dia. | φ35mm | φ50mm | φ70mm | φ90mm | φ100mm | φ120mm |

| L/D | 28:1 | 25:1 | 25:1 | 25:1 | 25:1 | 25:1 |

| Screw rotae speed | 110rpm(MAX) | 110rpm(MAX) | 90rpm(MAX) | 90rpm(MAX) | 70rpm(MAX) | 70rpm(MAX) |

| (PVC)Extruded capacity | 30kg/hr | 60kg/hr | 120kg/hr | 180kg/hr | 230kg/hr | 300kg/hr |

| Extruded wire dia. | 0.3-2mmφ | 0.5-5mmφ | 1.5-12mmφ | 5.0-35mmφ | 8.0-40mmφ | 8.0-40mmφ |

| Line speed | 600M/min (MAX) | 600M/min (MAX) | 600M/min (MAX) | 600M/min (MAX) | 600M/min (MAX) | 600M/min (MAX) |

| Pay off stand | 300mm rainbow motor driver | 500mm rainbow motor driver | 500mm power tension | 630mm power tension | 1000mm power tension | 1000mm power tension |

| Extruder motor | 11KW 4P AC motor | 15KW 4P AC motor | 22KW 4P AC motor | 37KW 4P AC motor | 55KW 4P AC motor | 75KW 4P AC motor |

| Auto feeding | 25KG(MAX) | 50KG(MAX) | 75KG(MAX) | 100KG(MAX) | 150KG(MAX) | 150KG(MAX) |

| Diameter controller | ±0.002mm | ±0.002mm | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm |

| Heat precision | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 |

| Cooling water sink | "W" shape single layer | "U" shape double layer | "U" shape double layer | "U" shape single layer | "U" shape single layer | "U" shape single layer |

| Capstan dia. | φ318mm doubel whees | φ318mm doubel whees | φ477mm doubel whees | φ477mm doubel whees | φ636mm doubel whees | φ636mm doubel whees |

| Capstan motor | 3.7KW 4P AC motor | 3.7KW 4P AC motor | 5.5KW 6P AC motor | 5.5KW 6P AC motor | 5.5KW 6P AC motor | 5.5KW 6P AC motor |

| Store wire length | 250M(MAX) | 250M(MAX) | 250M(MAX) | 200M(MAX) | 200M(MAX) | 200M(MAX) |

| Take up motor | 3.7KW 4P AC motor | 3.7KW 4P AC motor | 3.7KW 4P AC motor | 5.5KW 4P AC motor | 5.5KW 4P AC motor | 5.5KW 4P AC motor |

| Take up bobbin | φ300-500mm (MAX) | φ400-630mm (MAX) | φ400-630mm (MAX) | φ400-630mm (MAX) | φ600-1000mm (MAX) | φ3600-1600mm (MAX) |

| Packaging Detail:wooden case or other |

| Delivery Detail:25-30 days |