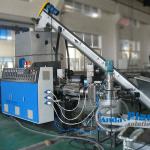

PE/PP/LDPE pelletizing line/granulators/pelletizing machine

| Condition:New | Type:Granulating Production Line | Capacity:150-800KG/HR | Place of Origin:China (Mainland) |

| Brand Name:QS MACHINE | Model Number:SJSZ92 | Material:LDPE | Screw Design:Double |

| Voltage:380V,50HZ,3P | Power:100KW-350KW | Dimension(L*W*H):15*3*5 | Weight:2500KG |

| Certification:CE | Warranty:ONE YEAR | After-sales Service Provided:Overseas service center available | Items:LDPE Pelletizing Line |

Applcaition

Recycling PP PE waste film,bags material,and make the material into pellets.

Process flow

Conveyor→Force feeder→First stage extruding system→First high speed Net exchanging system → second stage extruding system→Second high speed Net exchanging system and Die-head→ water tank→ air dryer→ pelletizer→ vibration sieve → Air Blower → Storage silo

Detailed description

1. Conveyor:convey PP PE flakes into force feeder tank.

2.Force feeder:feed flakes into extruder forcedly,to make the the production capacity high and stable.

3.First stage extruding system:plasticizing material and exhausting gas.

4.First high speed Net exchanging system:filter material impurity,to make production more stable.

5.Second stage extruding system:plasticizing machine again.

6.Second high speed Net exchanging systemand Die-head:filter material impurity and make material noodle strand.

7.Water tank:cooling material noodle strand.

8.Air dryer:drying material noodle strand.

9.Pelletizer:cutting noodle strand into pellet.

10.Vibration sieve:remove bad pellet and keep good pellet.

11.Air Blower:convey good pellets into silo.

12:Storage silo:keep pellet.

| No. | Name | Qty |

| 1. | Belt conveyer | 1set |

| 2. | Compactor machine | 1set |

| 3. | single screw extruder | 1set |

| 4. | Water-ring cutting machine | 1set |

| 5. | Vibrate screen | 1set |

| 6. | Dewatering machine | 1set |

| 7. | Storage | 1set |

Main Advantage :

- Screw and barrel are made of 38CrMoAlA, inlet mouth treated with special alloy: very strong and long life.

- Easy operation: it has automatic constant temperature control and stable performance. After adjusting well, 1 or 2 workers are enough to run this machine, to feed the materials and change pellet receiver.

- Low cost in using after redesign: now this kind machine is more economic in electric power source and also water. In the long working life of this machine, it can save many sources in energy!

- High output, long operating life and lower noise: it’s the ideal waste plastics regenerative pelletizer machine for nowadays.

| Packaging Detail:Standard Packaging |

| Delivery Detail:60days |