pe pp film pelletizing machine/pe pp film granulating machine/recycle plastic granules making machine

| Condition:New | Type:Granulating Production Line | Capacity:100-800kg/h | Place of Origin:Jiangsu China (Mainland) |

| Brand Name:sevenstars:pe pp film pelletizing machine | Model Number:SJ:pe pp film pelletizing machine | Material:PP/PE | Screw Design:Single |

| Voltage:380V 50HZ or customized | Power:37-90kw | Dimension(L*W*H):per different capacity | Weight:per different capacity |

| Certification:CE ISO | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas | plastic machine:PP PE pelletizing machine |

| pelletizing type:water ring pelletizer | Frequency convertor:ABB | Temperature controller:RKC | Motor:Siemens |

| material cooling:watercooling in water tank | plastic film pelletizing line:waste film recycling line/garbage recycling line/film pelletizing line | plastic pellet making machine:plastic pe pp film recycled granules | plastic granules making machine:recycle plastic granules making machine |

| name1:pe pp film pelletizing machine |

Feature and Function of pe pp film pelletizing machine:

Water ring type pelletizing line,recycling PP PE film bags,make them into pellets.

Process flow of the pe pp film pelletizing machine:

Conveyor→ PE film compactor→ Extruding system→ Die-head and High speed Net exchanging system→ water ring pelletizing machine → water tank → dewatering machine→ vibrating sieve→ Air Blower → Storage hopper

Detailed description of pe pp film pelletizing machine

1. Conveyor:convey PP PE film or flakes into compactor.

2. PE film compactor:crushing and compress film,and feed compressed film into extruder forcedly,to make the production capacity high and stable.

3.Extruding system:plasticizing material and exhausting gas.

4.High speed Net exchanging system and Die-head:filter material impurity,to make production more stable.

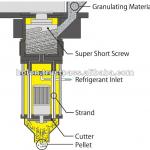

5.water ring pelletizing machine:cutting pellets in water.

6.Water tank:cooling pellets.

7.Dewater machine:make pellets dry.

8.Vibration sieve:remove bad pellet and keep good pellet.

9.Air Blower:convey good pellets into silo.

10:Storage silo:keep pellet.

Thecnical parameters of pe pp film pelletizing machine

Model | L/D | Output | Speed of Screw Rotation | Power | Center Height |

SJ-50/33 | 33:1 | 20-80 kg/h | 12.5-130 r/min | 37kw | 1000 mm |

SJ-65/33 | 33:1 | 80-150 kg/h | 33-130 r/min 20-120r/min | 45kw 55kw | 1000 mm |

SJ-75/33 | 33:1 | 120-280 kg/h | 20-120 r/min | 75kw 90kw | 1000 mm |

SJ-90/33 | 33:1 | 150-450 kg/h | 33.3-110 r/min | 110kw 160kw | 1000 mm |

SJ-120/33 | 33:1 | 300-600 kg/h | 20-100 r/min | 260kw | 1200 mm |

SJ-150/33 | 33:1 | 450-700 kg/h | 7-80 r/min | 315kw | 1200 mm |

key words

PE PP pelletizing pelletizer granulating granulator machine recycling production line

plastic pelletizing /granulating machine

pelletizing production line

| Packaging Detail:wooden case or wooden pallet for pe pp film pelletizing machine |

| Delivery Detail:45days for pe pp film pelletizing machine |