PCL Vertical shaft impact cusher(sand making machine)

| Condition:New | Place of Origin:Henan China (Mainland) | Brand Name:Kexing | Model Number:PCL series |

| Power(W):According to different styles | Dimension(L*W*H):According to different styles | Certification:CE ISO9001-2008 | Warranty:1 year |

| After-sales Service Provided:Engineers available to service machinery overseas |

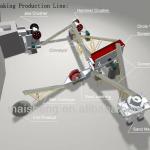

sand making machine

sand making machine Working Principle:

Sand making machine also named sand maker is a kind of advanced stone-crushing equipment in home and abroad with high-efficiency, which is designed by adopting the stone-beating-stone theory and technology from Barmac Company of America. The Sand making machine is widely used for crushing hard and brickle materials including various minerals, abrasive material, refractory material, cement, quartz, iron ore, etc.Sand maker is specially suitable for making sand for buildings, road building. The Sand making machine(sand maker) consists of inlet, material-scattering device, whorl crushing chamber, impeller, main shaft, base, transmission drive, motor, etc.

Sand Making Machine Application

the rod sand making machine is widely used in powder making production line in industries, like mining,building materials and chemistry industries. It is a key equipment to grind all kinds of ores and other materials, including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc.

Characteristics of Sand Making Machine

Simple structure and low operating cost;

High efficiency and low consumption;

Sand Making Machine has the function of fine crushing and crude grinding;

Slightly influenced by the moisture content of material, and the max moisture content is 8%;

More suitable for crushing mid-hardness and high-hardness materials;

Cubic shape of final products, high piling up density and low iron pollution;

More wearable and easy maintenance;

Low working noise and less dust pollution.

Sand Making Machine Technical Data

Model | Feeding size | Power | rolling speed of Impeller | Capacity | Dimensions | Weight(including motor) (T) |

PCL-600 | 30 | 2×30 | 2000-3000 | 12-30 | 2800×1550×2030 | 5.6 |

PCL-750 | 35 | 2×45 | 1500-2500 | 25-55 | 3300×1800×2440 | 7.3 |

PCL-900A | 40 | 2×55 | 1200-2000 | 55-100 | 3750×2120×2660 | 12.1 |

PCL-900B | 40 | 2×75 | 1000-1450 | 65-130 | 3750×2300×2090 | 13.6 |

PCL-1050 | 45 | 2×(90-110) | 1000-1700 | 100-160 | 4480×2450×3906 | 16.9 |

PCL-1250 | 45 | 2×(132-180) | 850-1450 | 160-300 | 4563×2650×3716 | 22 |

PCL-1350 | 50 | 2×(180-220) | 800-1193 | 200-360 | 5340×2940×3650 | 26 |

| Packaging Detail:export standard,nude pack,or as customers' request |

| Delivery Detail:within 15 days |