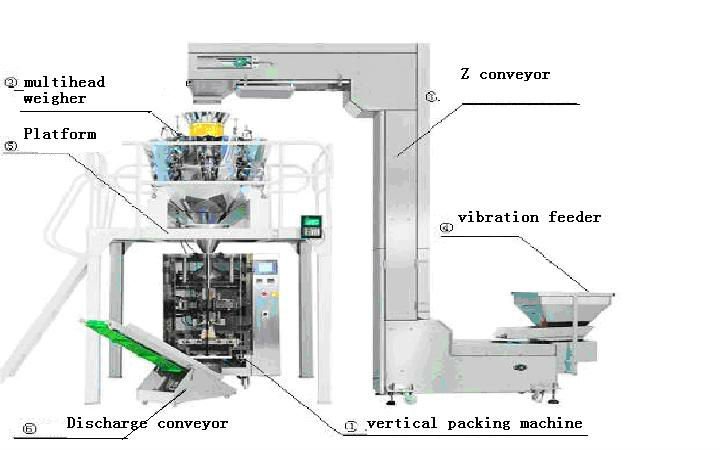

packing machine with multihead weigher

| Type:Packaging Line | Condition:New | Application:Food,Medical,Chemical | Packaging Type:Bags |

| Packaging Material:Plastic | Automatic Grade:Automatic | Driven Type:Electric | Voltage:110V or 220V |

| Power:5100 | Place of Origin:Guangdong China (Mainland) | Brand Name:JNYE | Model Number:JY-PL |

| Certification:CE | After-sales Service Provided:Engineers available to service machinery overseas | weighing heads:10 | packing:automatic filling sealing and cutting |

| date print:yes | language:13 different countries languages | CE:yes |

- Z conveyor and its feeder:)

The conveyer is applicable for vertical lifting of grain material in departments such as corn, food, fodder and chemical industry, etc.

For the lifting machine, the hopper is driven by the chains to lift. It’s used for vertical feeding of grain or small block material. It has advantages of large lifting quantity and highness.

The height of lifting: 360cm (discharging height 310cm)or others can be made according to customer’s need.

Conveyor speed controlled by inverter. Bucket movement controlled by level sensor.

Max 90buckets/min

Power: 550W Voltage: 220V

Size: 3200x435x3650mm

Packing size: 1) main body:200x120x110cm=2.64CBM, about 300kg gross weight

2) vibration feeder: about 0.7CBM, about 100kg gross weight

This elevator is for one weigher or one packing machine only, we can also make the elevator suit for several multihead weighers and several packing machines use at the same time. So that highly save your money.

2.JY-2000A multihead weigher:

Application scale:

Potato slice and chip, salads, raisin, oatmeal, candy, peanut, walnut kernel, apricot kernel, popped food, sugar, jelly, frozen dumpling, meatball, crude drugs, gourmet powder, salt, solid beverage etc.

Non food: screws, nuts, toys.

Features:

1. Can see each bucket weight through the screen

2. Can print out the machine working information (each dump weight, target weight, error, accuracy, speed, total bags, total weight...)by printer.

3. Can set the bucket open one by one, so that the big piece or easy break products will not discharge together and jam the input tube of the packing machines and reduce the break late of the products.

4. Can set the operator password, so that the user cannot change the main setting easily, easy for operator to manage the machine.

5. Up to 12 languages to choose.

6. Can set the bucket open time manually according to your need, so that the products will not block inside of the buckets.

7. Photograph eyes to check the products: if the products on the top corner is not enough for next dump, it will give signal to the packing machine to let it stop baging and at the same time will give the signal to the conveyor to let it send products.

8. Optional parts: collection bucket, reject function bucket (2open doors, one for the right weight products pass, one for rejecting the over/down weight products); printer

9.Net weight: 260kg, gross weight: 300kg

10.Packing size: 108X108X124CM

- Humidity: 35-85% (there should be no condensation)

- Password: The password system can be provided to protect the important parameters from tampering yb unauthorized person. The menu system is divided into three groups: Operator Level, Supervisor Level and Engineer Level.

- The clean out procedure is used to discharge all the product left on the cross-head feeder and the machine before changing product or at the end of daily production.

- If a bucket has trouble, such as ZERO ERROR , SPAN ERROR or ACTUATOR ERROR, you can inhibit the bucket and continue the operation of the system suing the rest of the heads(buckets).

- Counting mode: If the products are almost the same size and the same weight in piece, and you want the exact number piecs in each bag, use this function

- Over discharge:a combination exceeding the High limit can be discharge when this set to “ON”.

- AUTO ZERO INTERVAL: this used to set interval automatic zero reseting in min.

- Discharging in turn: this function used to weigh the easy break or fragile products, so that the products will not drop all together to hit each other. That is the bucket will discharge the weighed products one by one.

Technical:

|

3. Platform: 170X195X170CM

4. JY-13 vertical packing machine :

Features:

Suit for: OPP/CPP, CPP/PE, MST/PEand other types of heat sealing film

The touch-sensitive screen can display the state of machine, operation in struction and the state of breakdown in either Chinese and English, easy operation

It has a compact structure and every component has been made carefully, and the touching part of material are made by stainless steel

For guaranteeing stable ling-term operation of the machine, electrical equipments and pneumatic equipments are all made by famous manufacturers of the world

The date printer has an alarming equipment of no ink belt, without escaping printing.

Specification:

Packaging speed: 5-60bag/min

Bag making size: (L)50-300mm (W)60-200mm

Bag making type: pillow bag, vertical bag and make hole equipment (need to add extra money)

Filling range: 150-1300ml

Max packaging film width: 440mm

Film thickness: 0.04-0.08mm

Air consumption: 200L/min

Total power/ voltage: 2.2KW/220V, 50-60HZ

Outside size: 1400X970X1600mm

Gross weight: 400kg

Application:

Grain, strip and slice materials such as expanded food, shrimp cracker, candies, peanuts and popcorns.

Package for grain materials such as rice, salt, jelly, mung bean oatmeal and laundry powder.

Function:

The design of this machine is reasonable and elaborate. Its performance is stable and it is easy to handle. It can cut the edge of every single bag or every several joint bags according to specific requirement. All proceedings of feeding, measure, bag-making, date printing, filling, puffing, sealing, cutting and outputting finished products are finished automatically.

5. Discharge conveyor:

| Feeding speed | 30m/minute |

| dimension | 2110×340×500mm |

| Voltage | 220V/45W |

| Packing size | 179x48x53cm |

| Net weight | 60kg |

| Gross weight | 85Kg |

| Packaging Detail:wooden case |

| Delivery Detail:20-30days |