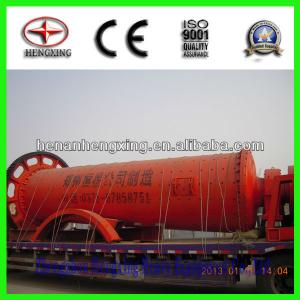

Ore dressing line wet ball mill from Hengxing

| Condition:New | Type:Ball Mill | Motor Type:AC Motor | Power(W):18.5-800kw |

| Capacity(t/h):0.65-90 | Place of Origin:Henan China (Mainland) | Brand Name:Hengxing | Model Number:0.9x1.8m-3.2x4.5m |

| Dimension(L*W*H):diameter1.83m length 7m | Weight:3.6-137t | Certification:ISO, CQC, CE | Warranty:One year |

| After-sales Service Provided:Engineers available to service machinery overseas | Color:as your request | wet ball mill spare parts:supplied | grinding way:wet |

| liner type:High Mn or rubber type according requirement | Feed size:max 25mm | grinding media weight:1.5-65t | Application:ore dressing |

| Installation:As our engineer' guidance | Pre-sale:Choose suitable model according to your situation | mating equipment:motor, reduction box, control panel, anchor screw included |

Wet Ball Mill

Wet Ball mill introduction

Wet ball mill is a cylindrical device used to grind (or mix) materials like ores,chemicals, ceramic raw materials and paints. Ball mill rotate around ahorizontal axis, partially filled with the material to be ground plusthe grinding medium. Different materials are used for media, includingceramic balls, flint pebbles and stainless steel balls

Wet Ball mill working pricinple:

Wet Ball mill,a kind of horizontal drum-type rotating device, is a grate mill withexternal gear and double bins. Materials shall be evenly charged through quill shaft in feeding device into the first bin, which hasstep or waved lining with steel balls in different specifications.Steel balls are taken to a certain height by centrifugal force from drum rotation and then fall. Thus it will give a heavy blow to materials, playing a role of grinding. Materials after crushed in thefirst bin shall enter bin across single-layer diaphragm into the second, which is provided with flat lining with steel balls, to go through further grinding. Powder shall be discharged from discharging grating, ending the milling process.

Wet Ball mill feature:

Wet Ball mill is mainly composed of charging and discharging, cyclone and rotation parts (like redactor, minor rotationgear, motor, electric machine, etc). Hollow axis is made of steel partswith a lining replacable. Major rotation gear, machined by rollingwheel of casting, is lined with wearing plate with fine wear-resistingproperty

This machine runs stably and reliably. Based on difference of materials and discharging types, dry Ball mill and wet Ball mill are selectable

Technical datas of Hengxing wet Ball Mill

| Model | Rotary speed(r/min) | Ball load(t) | Feeding size(mm) | Discharging size(mm) | Capacity (t/h) | Motor power(kw) | Weight(t) |

| Ø900*1800 | 36-38 | 1.5 | <=20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

| Ø900*3000 | 36 | 2.7 | <=20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

| Ø1200*2400 | 36 | 3 | <=25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| Ø1200*4500 | 32.4 | 5 | <=25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| Ø1500*3000 | 29.7 | 7.5 | <=25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

| Ø1500*4500 | 27 | 11 | <=25 | 0.074-0.4 | 3-6 | 110 | 21 |

| Ø1830*3000 | 25.4 | 11 | <=25 | 0.074-0.4 | 4-10 | 130 | 28 |

| Ø1830*4500 | 25.4 | 15 | <=25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

| Ø2100*7000 | 23.7 | 26 | <=25 | 0.074-04 | 8-48 | 280 | 50 |

| Ø2200*4500 | 21.5 | 27 | <=25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

| Ø2200*7500 | 21.7 | 35 | <=25 | 0.074-0.4 | 15-30 | 380 | 56 |

| Ø2400*3000 | 21 | 23 | <=25 | 0.074-0.4 | 7-50 | 245 | 54 |

| Ø2400*4500 | 21 | 30 | <=25 | 0.074-0.4 | 8.5-60 | 320 | 65 |

| Ø3200*4500 | 18 | 65 | <=25 | 0.074-0.4 | ----- | 800 | 137 |

Wet ball mill

Wet ball mill delivered from hengxing company:

Zhengzhou hengxing heavy equipment co., ltd specialized in various kinds of wet ball mill, cement mill, mining ball mill and etc.

You are welcome to us! Call Rocky:0086-18837173732

| Packaging Detail:seaworthy packaing, spare parts packed in wooden case |

| Delivery Detail:one month after deposit payment(one week if stock available) |