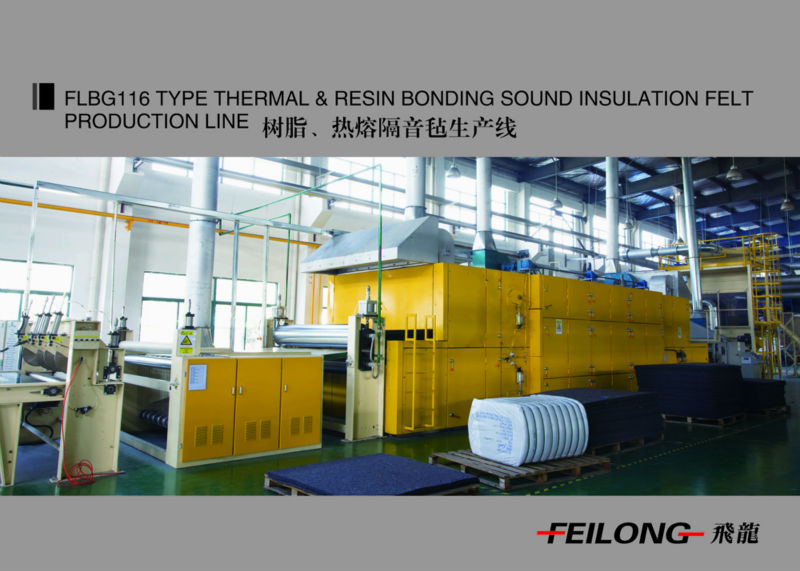

Nonwoven Resin felt production line

| Condition:New | Automatic Grade:Automatic | Place of Origin:Jiangsu China (Mainland) | Brand Name:FEILONG |

| Model Number:FLBG--250 | Voltage:380v | Power(W):300kw | Dimension(L*W*H):depend on machine |

| Weight:400T | Certification:GB | Warranty:one year | machinery:gray |

Main technical Parameters of the line

1.1 Working width:2500mm;

1.2 Finished product:≤ 2200mm;

1.3 Suitable for use of material:

Glass fibre, PP, ES fibre, Phenolic resin, Staple PET, granule of sponge

1.4 Capacity:1000kg/h

1.5 GSM:400g/m2-2000g/m2;

1.6 Thickness:5mm-60 mm;

1.7INFORMATION:Forming line mechanical speed:2-12m/min (Provided by the company Hermann);

1.8 Compressed air:0.6-0.8mpa,Capacity≤1m3/h(Never judges)

1.9 Power:three phase:415V, single phase:220V, Frequency:50Hz;

1.10 Installed power: to be confirmed by supplier.

1.11 Controlling:

PLC touch screen control

1.12 Application of the line:

Fibre hot melt felt, advanced epoxy resin or cured epoxy resin felt, use for automotive interior, air condition deadening felt, insulation quilt, foundation fabric for carpet etc….

1.13 Heating method:Saturated steam or superheated steam injection

1.14 Heating Temp:≤220°C

Steam pressure.:1.25Mpa

(according to steam pressure of customer)

1.15 Capability of steam:about 800kg/hr

1.16: Formulas:

| PET FIBER 6D-56 mm regenerated | PET BINDER 4D-32 mm native | COTTON SHODDY | GLASS FIBERS Recycled 23 mm length 13-20 microns | RESIN | |

| THERMOPLASTIC | 50% | 15-20% | 30% | ||

| THERMOSETTING-1 | 70-80% | 20-30% | |||

| THERMOSETTING-2 | 55% | 15% | 30% |

1.17 Operation direction:To be confirmed

1.18 Colo:To be confirmed

| Packaging Detail:according the customer request |

| Delivery Detail:denpend on the order |