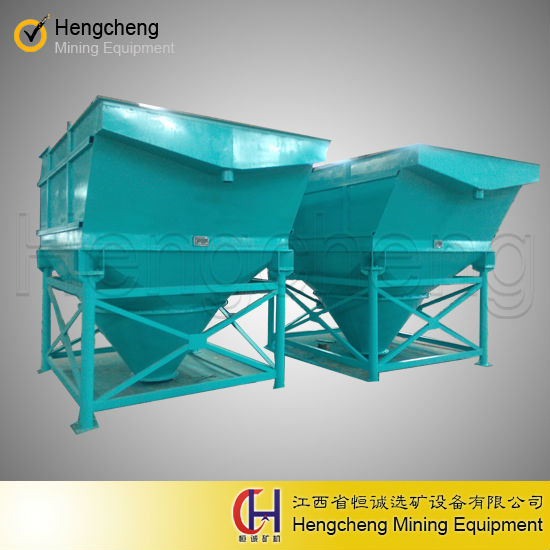

New designed pulp thickener with small dimension

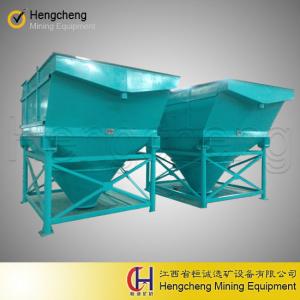

| Type:Mining Thickener | Condition:New | Application:mineral processing | Motor Type:no power |

| Power(W):0 | Production Capacity:100 | Place of Origin:Jiangxi China (Mainland) | Brand Name:Hengcheng |

| Model Number:TY | Dimension(L*W*H):3580x2350x3500MM | Certification:ISO9001 | Warranty:1 year |

| After-sales Service Provided:Engineers available to service machinery overseas | mineral pulp concentrate capacity:300-800/500-1500 t/d | wastwater recycling capacity:100-1500 t/d | overall dimension:customized |

| color:customized | installaton:under guidance |

New designed pulp thickener with small dimension

Description:

TY series of ramps and efficient dense (grade) box is in the "shallow subsidence theory" developed on the basis of a new generation of efficient settlement of enrichment equipment. The device combines a regular ramps thick and deep cone thickener tank advantages: small footprint, More efficient settlement. High concentrations of discharge. In recent years, widely used in metallurgy, mining, chemicals, ceramics, coal, etc.

Working principle:

the pulp or other to be processed liquid condensed from feeding zone intothe subsidence area,In this area, form the relatively dynamic balanced suspension process;the larger size particles in the pulp, due to its settlement at the end of the speed isfaster,and overcoming the flow pulse power,was filtered by filter layer in the subsidence area, then quickly condensed into the bottom discharging hole and be discharged. Those small size particle failed to overcome the flow force, will rise along with the rising water into the inclined tube district.

The inclined tube district is full of the hexagonal thin porous inclined tubes according to certain angle, so Water can be divided into many of the precipitation units. Thefiner particles into inclined district reached inclined tube wall under the condition of laminar flow hydraulic settlement, accumulate to certain amount, under the action of gravity slide to the subsidence area. According to the design requirements ofthe separation size and processing ability, the fine particles which failed to be settled in inclined tube district, will be discharged with the overflow water. So finish the separation and process of precipitation.

Features:

1. small scale, small cover area, low purchase and install cost, covers an area of 1/12-1/20 of old thick pool, purchase cost is half of old thick pool.

2.advanced technology and high efficiency. Could finish the separation in the machine, after concentration could get the recyclable metallic mineral, or couldreduce wastewater emissions and water recycling.

3.energy saving effect is good. This machine with no power, save the electric consumption; and the water after subside and filter could be standardized sluicing, and recycling. This could reduce 60-80% amount of wastewater emission.

Specification:

| MODEL | Dimension | pulp thickening(t/d) | Water recycling (t/d) |

| TY-5 m2 | 3580x2350x3500 | 300-800 | 500-1000 |

| TY-10 m2 | 7160x2350x3500 | 500-1500 | 100-1500 |

More Pics for reference:

Jiangxi Hengcheng Machinery Factory is a professional manufacturer of kinds ofmining machinery, and Hengcheng has a rich experience in beneficiation of kinds of ores,flow sheet and plant allocation can be designed for you.

If samples of 20kgs can be available from you, a mini test can be done for you to prove the beneficiation efficiency.

Service Line: +86-18970706487

Service Skype: bean-lai

| Packaging Detail:export container load |

| Delivery Detail:in 30 days |