new design wood pellet machine price easy operate & maintance

| Place of Origin:Henan China (Mainland) | Brand Name:Dahua | Model Number:450 | Condition:New |

| After-sales Service Provided:Engineers available to service machinery overseas | Application:wood, sawdust, sugar cane, bamboo, rice husk, grass, straw | Type:Multi | Production capacity:0.3-10 t/h |

| weight:14t | Certificate:ISO9001,SGS | Color:Any color | Motor band:Made in China or as client's request |

| Factory visit:Welcome | Installation:Under the engineer's guide | mould:8-30mm |

Zhengzhou Dahua Mining Machinery Co,LTD is famous and professional manufacturer of rotary dryer in China .

we not only offer best machines to our customer, but also we offer engineer to install and trail run machine for our customer

if you are interested in our products ,plz feel free to contact me :Ms Carrrie 15036078775

Basic features: Contact :Ms Carrie tel:0086-15036078775

Advanced of us

1. Unique Design, stable operation

2. Over 15 years experience and more than 300 sets key pellet lines

3. Suitable for large scope of raw material, such as sawdust, rice husk, straw grass, peanut shell, branch , scobs, , etc.

4.High capacity and low energy consumption

5.Siemens motor and imported bearing

6.Wide applicable scope:It can process different materials such as biomass materials like wood, sawdust, sugar cane, bamboo, rice husk, grass, straw,etc, and some special raw materials like rubber, clay and plastic as well.

7.Adjustable capacity: We can customize the different capacities from 0.3 ton per hour to 30 ton per hour or even more.

8.After-sale guarantee:One year warranty and all round after sale service

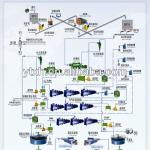

1.Wood pellet line :

1.Wood pellet line is high automation,high-tech,,which can save a lot maintenance time. With high accuracy specification,simple structure, easy operation

2.Widely Scope:All kinds of biomass raw material ,such as industrial waste,wood sawdust,rice husk,palm fiber.

2.Working principle and process detail:

1.Material come from belt conveyor and then into the storage,screw conveyor feed material automaticllly to the pellet forming chamber

2.In the forming chamber ,two gear and mold help to form and press pellet,Gear rotate to press pellet come out surround.

3.Automatic cutting machine arround the mold ,which can cut pellet automaticly,it can also adjust the length of pellet .

4.During the process ,the oil supply device can lubricate the gear and mold.

3..Pellet features

1.Pellet is new-style energy which is renewable, environmental protection,it is also clean and low cost.

2.Pellet (biomass briquette,biomass pellet,wood pellet) is used in heating, biomass boiler, household gasification furnace, industrial boiler, hotels, restaurants, bath in industries as heat source,instead of coal in boiler burning,avoid the pollution of burning the coal ,also being used as industial fuel.

3.High density from 0.9-1.6g/cm3,easy to store and transportation,Calorific value can be 3500-5500Kilocalorie.

4.Biofuel can instead of coal for biomass power generation.

4.Raw material required:

1.All kinds of biomass material,or farm waste ,such as cotton stalk,corn straw,wheat straw,sawdust,peanut shell,rice husk,animal manure.

2.Moisture:10%,6mm

5.Our advantage:

1.Long history in wood pellet machine and biofuel briquette machine making,has export to more than 20 countries.

2.Our product with high automation which can save labor,and it is also easy to maintenance ,save a lot of maintenance time.

3.Our machine is flat location stainless steel ring die mold and gear,which is different from Vertical location ring die machine ,which has a good performance.

Introduce of technical data

| model | CXJ | CXJ-1 | CXJ-2 | CXJ-3 |

| power | 22kw | 30 kw | 37 kw | 45 kw |

| capacity | 0.5-0.8t/h | 0.6-1 t/h | 1-1.5 t/h | 1.2-2 t/h |

| Dimension | 2000*900*1600 | 2000*900*1700 | 2200*1000*1700 | 2200*1000*1700 |

| weight | 1300kg | 1500 kg | 1600 kg | 1700 kg |

| Model :MXJ-C5 | Technical data |

| oversize[L×W×H](mm) | 3000×1480×1920 |

| power(KW) | 37-90kw |

| capacity(kg/h) | 1000~5000 |

| Rotate speed(r/min) | 166 |

| Quality of mould(piece) | 36 |

| Size of mould(mm) | 30-33mm |

| Raw material moisture% | 10-30 |

| Density of final products/cm3 | 0.6-1.42 |

| Length of final products(mm) | 30-200 |

| Packaging Detail:container ,samller parts in the wooden box |

| Delivery Detail:7 days or 15 days |