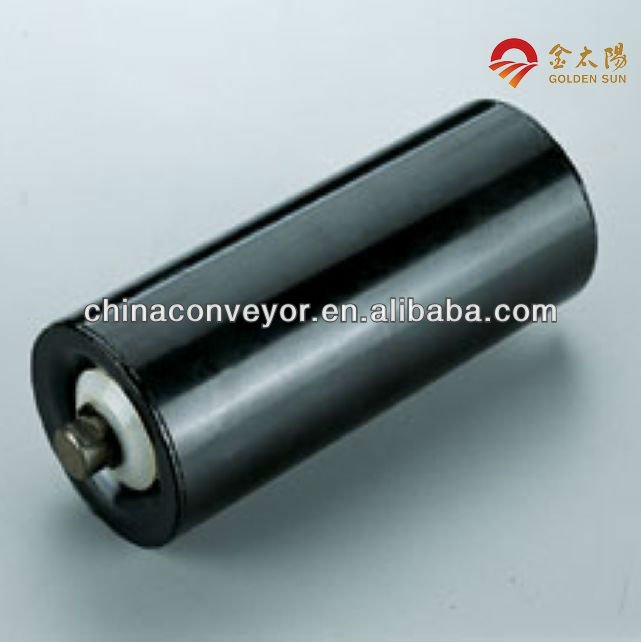

New design V type carrier conveyor steel roller&idler for mining washing by ISO/CE largest/biggest manufacturer

| Condition:New | Type:Single Drum Roller | Static Linear Pressure:as your request | Travel Speed:at least 5m/s |

| Grade Ability:good | Place of Origin:Hebei China (Mainland) | Brand Name:Goldensun | Model Number:TD75,DTII,DTIIA |

| Power(W):2m-2.5m/s | Dimension(L*W*H):length 190mm-3500mm | Weight:3kg-39kg | Certification:CE ISO SGS,CE, ISO,SGS |

| After-sales Service Provided:No overseas service provided | Using country:US,Canada,UK,German,Brazil | Processing Quantity::360,000 pieces per year | Color:Black,Blue,Red or as your request |

| Tube::Seamless pipe | Bearing:Deep grooved ball bearing, the brand can be as requested | Shaft material:Cold drawn steel, C45 or as requested | Life time:More than 30000 hours |

| Specification:According to the customers' requirements | Application:Coal mining industry, cement, harbor, crushing and screening industry |

New design V type carrier conveyor steel roller&idler for mining washing by ISO/CE largest/biggest manufacturer

=

| Diameter: | 50-219mm. | MOQ: | 5set |

| Length: | 150-3500mm. | Certification: | ISO,CE,SGS |

| Lifetime: | 30,000 hours. | Port of loading: | Tian jin port |

| Type conveyor: | DTII, DTII (A),TD75 | Payment | T/T |

| Tube | Carbon steel tube/ seamless steel tube. |

| Shaft | 20# Cold drawn steel, or as request. |

| Bearing | Single&Double Row Deep Groove Ball Bearing. |

| Seals | Grease retaining inner seal with Multi-stage Labyrinth and Retention Cap with Outboard Rubbing Flinger Seal. |

| Lubrication | Grease is Lithium soap type grease with Rust Inhibitors. |

| Welding | Mixed gas shielded arc welding end. |

| Painting | Ordinary painting, hot galvanized painting, electric static spraying painting, baked painting. |

Summary of the belt conveyor roller size:

| Diameter(mm) | Length scope(mm) | Shaft diameter(mm) | Shell wall thickness(mm) |

| 89 | 150-2500 | 20,25 | 3.2-6 |

| 102 | 25,25,30 | 3.5-6.0 | |

| 108 | 25,25,30 | ||

| 114 | 25,25,30 | ||

| 127 | 25,25,30 | ||

| 133 | 25,25,30 | ||

| 140 | 25,25,30 | ||

| 152 | 25,25,30 | 4.0-6.0 | |

| 159 | 25,25,30 | ||

| 165 | 25,25,30,40,45 | 4.5-6.0 | |

| 177.8 | 25,25,30,40,45 | ||

| 190.7 | 25,25,30,40,45 | ||

| 194 | 25,25,30,40,45 | ||

| 219 | 25,25,30,40,45 |

Flow chart of manufacturing process of belt conveyor roller:

Factory scene:

Customers:Frequently Asked Question of Our Customers:

Q: What are we doing?

A: We specialized in manufacturing and designing conveyors and accessories(conveyor roller, conveyor pulley, frame etc) for 19 years.

Q: What’s the advantage compared to other suppliers?

A:We provide belt conveyor and accessories with competitive price and superior service. We have professional sales team, production team, researching team.

Q:How is our customer service?

A: all our sales representatives can speak fluent English. They will answer all of your questions in 24 hours.

Q:What others can we offer?

A: Based on the wide product range, we offer the best One-Stop sourcing service. We will definitely save you a lot of time and money, and based on our huge quantity of shipment, we can get the best shipping service from the best forwarders.This will also help you to save a lot on the shipment.For the installing of the large-scale belt conveyor, overseas service is accessible for us.

Q:What is the MOQ of our products?

A:The MOQ for unloading roller is 5 pieces.

Q:What is the payment of our company?

A. Both TT and L/C is acceptable for us.

| Packaging Detail:1.Seaworthy wooden packing case 2.Bundling package 3.Container |

| Delivery Detail:According to the number of buyers' order |