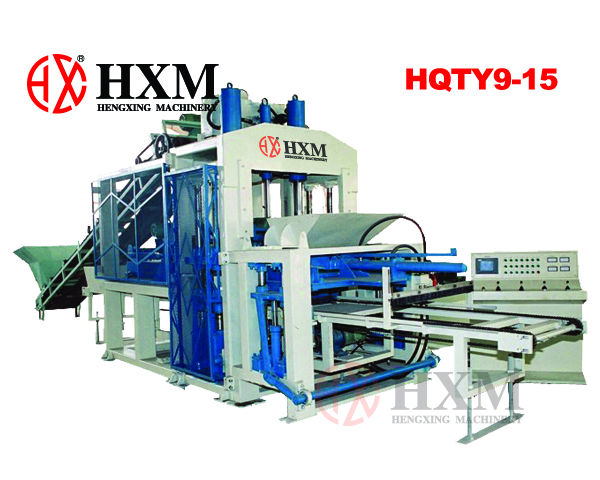

New Design for 2013 Concrete brick block making machine (HQTY9-15)

| Condition:New | Type:Paving Block Making Machine | Brick Raw Material:Concrete | Processing:Brick Production Line |

| Method:Hydraulic Pressure | Automatic:Yes | Capacity:400*200*200mm: 1,500 pcs/hour | Place of Origin:Fujian China (Mainland) |

| Brand Name:HENGXING | Model Number:HQTY9-15 | Voltage:380v | Power:38kw |

| Dimension(L*W*H):3560x2600x2950mm | Certification:ISO,CE | Warranty:one year | After-sales Service Provided:Engineers available to service machinery overseas |

| Weight:10T | Frame:Heavy dutty steel structure | color:yellow | bricks:concrete bricks |

| control:PLC automatic | PLC:Mitsubishi | Mould steel:Manganese steel #16 |

New Design for 2013

Concrete brick block making machine (HQTY9-15)

Main Technical Specification | |

Production | 9pcs/mould, 13,000pcs/8 hours(Hollow block:400x200x200mm) |

| 50pcs/mould, 75,000pcs/8 hours(solid block:240x115x53mm) | |

| 25pcs/mould, 37,000pcs/8 hours(interlock:240x130x60mm) | |

| 33pcs/mould, 49,000pcs/8 hours(paver block:200x100x60mm) | |

| Working cycle time | 15-20s |

| Main machine dimension | 3560x2600x2950mm |

| Main machine weight | 10.5T |

| Main machine power | 42kw |

| Vibration force | 70kn |

| Pallet size | 1350x720x25mm |

| Factory area | 1000 square meters |

New Design for 2013

Concrete brick/block making machine

of main technical features:

1, controll system(Mitsubishi PLC):

A.Mitsubishi PLC, Taiwan Touch Screen

B.Omron Relay, Schneider Contactor

C.Control Panel with pictures.

2, hydraulic system(Taiwan):

A. Proportional electro-hydraulic relief valves

B. Solenoid directional valves

C. Pressure control valves

D. Water cooling system

E. Hydraulic Tank with oil filter

3, Table Vibration System, High frequency low amplitude

A. table vibration withHIGH FREQUENCY LOW AMPLITUDE

B. press head has threee Oli Cylinders

C. vibration platform hasfixed supportbar and adjustable support bar

4, Mould

A.use the 16#manganese steel

B. Line cutting machine to make sure 100% accurate size of mould

C.heat treatment can reach HRC 61

D.Based on the customer requirement to make the various moulds,

like hollow block, solid block, interlock block, curbstone block etc.

5, Feeder

A.the fork is working about 40 degrees to push the material into the mould

B. it can feed the various materials to the various moulds

This is the highly automaticNew Design for 2013Concrete brick block making machine , auto weighing system, auto mixing, auto makingconcrete brick. this New Design for 2013Concrete brick block making machine can make various blocks, like hollow blocks, paver, interlock, just change the mould. thisNew Design for 2013Concrete brick block making machine can be working two shifts, every shift shall be maintained very well, like clean the Moulds, Feeder, Mixer etc. this kind ofNew Design for 2013Concrete brick block making machine is very popular in the world, like Oman, Russia, Iraq etc.

these are site picture for theNew Design for 2013Concrete brick block making machine of factory

| Packaging Detail:The block machine and other steel structures will be packed nakedly in the container. The electrical components will be packed in strong wood cases with the above shipping mark clearly printed on each package. It must be suitable for long distance transportation. |

| Delivery Detail:30-45 DAYS |